Tech Tip 27 Shift Lever Tune up

| Tech Tip #27 Shift Lever Tune-up |

|

Tune-up your Shift Lever!

If your transmission is notchy and you are missing shifts, before you blame your transmission for your shifting problems, consider that your real problem just might be with your shift lever. The average shift lever leads a hard life. It is beat on by boots of all sizes, and is universally neglected by all, until it actually falls off!

Let’s address problems that can occur to shift levers that will affect shifting performance.

Bent Shift Pad:

The shift pads can become bent upward or downward or the pad can be bent back from impacts. The pads must be parallel to the plane of the footpeg and parallel to the ground. Use a Crescent® wrench to realign the shift pad to both planes.

The shift pads can become bent upward or downward or the pad can be bent back from impacts. The pads must be parallel to the plane of the footpeg and parallel to the ground. Use a Crescent® wrench to realign the shift pad to both planes.

The shift pads can become bent upward or downward or the pad can be bent back from impacts. The pads must be parallel to the plane of the footpeg and parallel to the ground. Use a Crescent® wrench to realign the shift pad to both planes.

The shift pads can become bent upward or downward or the pad can be bent back from impacts. The pads must be parallel to the plane of the footpeg and parallel to the ground. Use a Crescent® wrench to realign the shift pad to both planes.

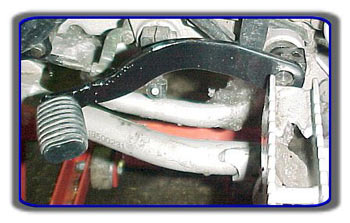

Shift Arm:

Shift Arm: motor, such as the recoil housing, the limited arc of the shift leverIf the shift arm is in any way contacting any part of the before it hits the motor may not be enough to impart enough rotation to the shift drum, causing a “missed” shift.

Pinch Clamp:

It seems the clamp bolt always works itself loose but is never tightened. When the pinch clamp is left in a less than tight condition, the clamp splines as well as the matching splines on the shift shaft wear. Wear on the shift lever can be easily repaired by the purchase of a new, easily replaced lever. Replacement of the shift shaft is much harder, and more expensive. And, No, WE do not WELD the shift lever to the shift shaft! If you find the “C” clamp is not tightening up on the shift shaft, even though the bolt is tight, DO NOT KEEP TIGHTENING THE BOLT! When it breaks, the shift lever is left loose and you will not be able to remove the shift lever! It is better to check for a gap in the “C” of the clamp. If the gap is non-existent, the fix is to place the shift lever in a vise and squeeze the “C” gap until closed. Use a hacksaw to make a cut down between the “C” of the clamp. Retighten the vise and re-cut the slot a second time. When reinstalled on the worn shift shaft, the shift levers “C” clamp will now tighten up, providing there are any splines left to bite into.

It seems the clamp bolt always works itself loose but is never tightened. When the pinch clamp is left in a less than tight condition, the clamp splines as well as the matching splines on the shift shaft wear. Wear on the shift lever can be easily repaired by the purchase of a new, easily replaced lever. Replacement of the shift shaft is much harder, and more expensive. And, No, WE do not WELD the shift lever to the shift shaft! If you find the “C” clamp is not tightening up on the shift shaft, even though the bolt is tight, DO NOT KEEP TIGHTENING THE BOLT! When it breaks, the shift lever is left loose and you will not be able to remove the shift lever! It is better to check for a gap in the “C” of the clamp. If the gap is non-existent, the fix is to place the shift lever in a vise and squeeze the “C” gap until closed. Use a hacksaw to make a cut down between the “C” of the clamp. Retighten the vise and re-cut the slot a second time. When reinstalled on the worn shift shaft, the shift levers “C” clamp will now tighten up, providing there are any splines left to bite into.

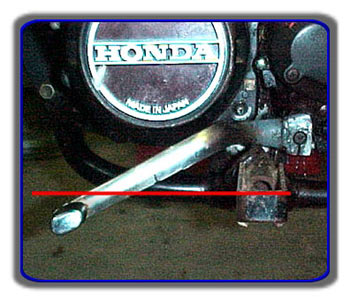

Misaligned Shift Pad:

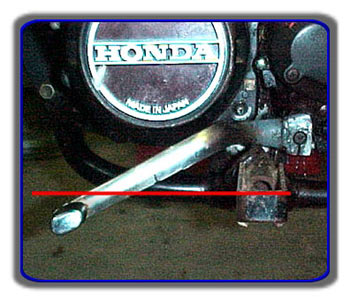

The next item to address is the height of the shift pad. Generally, the shift pad should be aligned, height-wise, with the top of the footpeg. This one is obviously low! Some manufacturers, such as Honda, dimple a mark into the end of the shift shaft that is meant to be aligned with a corresponding mark on the shift levers “C” clamp. On some machines, the lever throw required to make an up shift is so great that a human ankle simply can not rotate high enough. In this case, removing the shift lever and lowering it one spline can make riding much more enjoyable.

footpeg. This one is obviously low! Some manufacturers, such as Honda, dimple a mark into the end of the shift shaft that is meant to be aligned with a corresponding mark on the shift levers “C” clamp. On some machines, the lever throw required to make an up shift is so great that a human ankle simply can not rotate high enough. In this case, removing the shift lever and lowering it one spline can make riding much more enjoyable.

The next item to address is the height of the shift pad. Generally, the shift pad should be aligned, height-wise, with the top of the

footpeg. This one is obviously low! Some manufacturers, such as Honda, dimple a mark into the end of the shift shaft that is meant to be aligned with a corresponding mark on the shift levers “C” clamp. On some machines, the lever throw required to make an up shift is so great that a human ankle simply can not rotate high enough. In this case, removing the shift lever and lowering it one spline can make riding much more enjoyable.

footpeg. This one is obviously low! Some manufacturers, such as Honda, dimple a mark into the end of the shift shaft that is meant to be aligned with a corresponding mark on the shift levers “C” clamp. On some machines, the lever throw required to make an up shift is so great that a human ankle simply can not rotate high enough. In this case, removing the shift lever and lowering it one spline can make riding much more enjoyable.Shift Lever is wrong length:

If the shift lever pad does not fall directly behind the toes, each shift will require the rider to move his foot off the footpeg to make a “clean” shift instead of rotating the ankle. Additional length can be gained with a piece of metal welded into the shank.

Conversely, removing a piece of the shank can shorten the lever. It is best to do all cutting about 1in. back from the shift pad, on a straight section of lever shank. The relocated shift pad must be parallel to the ground and foot peg as outlined above.