Chinese Quad - Magneto tips

#1

I am currently trying to get a spark on a chinese quad, 250. The thing is brand new, just started a couple of times, ran for about twenty minutes and then decided to stop sparking. Tried swapping out the CDI (no change, maybe the new one is bad?). removed the kill switch wire from the cdi harness, no change. Tried to take a look at the magneto pulsar coil but when I went to remove the cover found that it is also bolted with a nut which (inset into the case) appears to be connected to the Crank. Anybody tackled one of these projects or can you direct me to a manual that may show the process. I am a bit stumped by this and don't know if I should drain the oil, remove the nut from the crank so I can get into the magneto. Electrical is a pain in the neck!

#2

Hey Sanford.

I have Canadian 08 Geo Quad, which had spark issues.

The flywheel key-way had moved which changed the timing.

To repair this, I had to remove the Flywheel-Magneto.

I would check the coil and your wiring for any shorts that would prevent spark before trying the Magneto.

If you are going to try the Magneto, I would recommend the following tools, Flywheel puller, & a Air Impact gun.

Can give you some direction If yours is a Geo.

I have Canadian 08 Geo Quad, which had spark issues.

The flywheel key-way had moved which changed the timing.

To repair this, I had to remove the Flywheel-Magneto.

I would check the coil and your wiring for any shorts that would prevent spark before trying the Magneto.

If you are going to try the Magneto, I would recommend the following tools, Flywheel puller, & a Air Impact gun.

Can give you some direction If yours is a Geo.

#3

Sanford.

Found this link on Page 2 of this Form.

How to check for Spark on a Chinese ATV.

http://www.buyatvsonline.com/k...-228_21.html#no-spark

Hope it helps

Found this link on Page 2 of this Form.

How to check for Spark on a Chinese ATV.

http://www.buyatvsonline.com/k...-228_21.html#no-spark

Hope it helps

#4

I worked on a Cool Sport 110 with a Loncin engine. I found a black box on the front near the steering shaft about the size of a cigarette pack. I think it was for the remote start and kill switch. I unplugged the wire from the box and the engine started firing again. It ran like new. Might not be Your problem but its just a thought. I have been told to always check every connection and ground wires first because these machines have alot of problems caused by the small wires and light weight crimp-on ends.

#5

Join Date: Dec 2008

Location: Tracy, California, USA

Posts: 3,260

Likes: 0

Received 12 Likes

on

12 Posts

Did you remove the kill switch wire out of the harness right at the CDI? There are often three kill switch connections throughout the harness, any one of which can kill the engine. The best way to eliminate them all at once is by disconnecting the kill connection at the CDI.

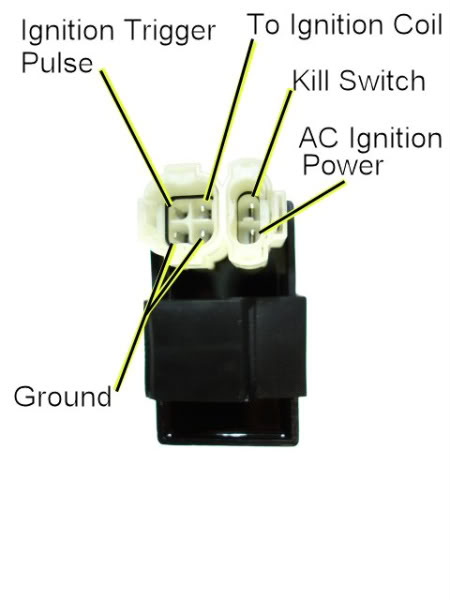

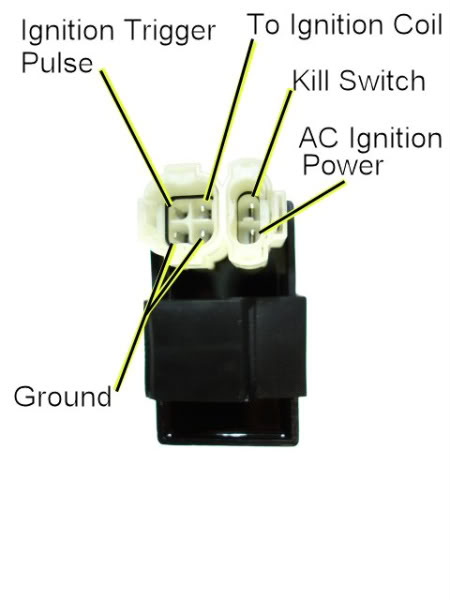

Is this your CDI?

If this is your CDI you can see the connection that must be disconnected to eliminate all the kill switches.

You can measure the stator ignition windings for proper operation without having to take the flywheel off. There are two windings: AC Ignition Power and Ignition Trigger. (There is another winding in the stator is used to charge the battery which I will ignore in this post since it has nothing to do with spark.)

Disconnect the CDI. Use a voltmeter to measure the AC ignition power connection in the wiring harness to engine ground while cranking. It should be 80 volts AC or so. Be sure you measure this on your voltmeter AC scale and not DC. This winding in the stator provides power to run the CDI, ignition coil, and spark. If it isn't putting out voltage then the ignition system won't work. Also, do not measure this voltage with the CDI hooked up. It won't hurt anything, but you will get meaningless results.

Next measure the voltage on the ignition trigger wire voltage to engine ground. It should be 0.1 to 0.4 volts AC while cranking. This is actually a complex waveform that doesn't measure well with a regular voltmeter, but you should see some small AC voltage when the engine is cranking. This connection provide a pulse that tells the CDI when dump all that power it has been storing up from the AC ignition power connection onto the ignition coil primary.

Both of these connections should also read resistance to engine ground. Go to the ohmmeter scale and measure the resistance to ground for both those windings at the CDI connector. The AC power widing should be 500 ohms or so (which is the same as 0.500 KiloOhms). The Trigger winding whould read 150 ohms or so. While you are measuring resistances make sure the ground wire(s) in the wiring harness are really connected to engine ground (zero ohms).

Ther are more things that can be measured. This should get you started. Electrics are not difficult with a voltmeter, a little common sense, and some practice. Report back what you measure and we'll go from there.

Is this your CDI?

If this is your CDI you can see the connection that must be disconnected to eliminate all the kill switches.

You can measure the stator ignition windings for proper operation without having to take the flywheel off. There are two windings: AC Ignition Power and Ignition Trigger. (There is another winding in the stator is used to charge the battery which I will ignore in this post since it has nothing to do with spark.)

Disconnect the CDI. Use a voltmeter to measure the AC ignition power connection in the wiring harness to engine ground while cranking. It should be 80 volts AC or so. Be sure you measure this on your voltmeter AC scale and not DC. This winding in the stator provides power to run the CDI, ignition coil, and spark. If it isn't putting out voltage then the ignition system won't work. Also, do not measure this voltage with the CDI hooked up. It won't hurt anything, but you will get meaningless results.

Next measure the voltage on the ignition trigger wire voltage to engine ground. It should be 0.1 to 0.4 volts AC while cranking. This is actually a complex waveform that doesn't measure well with a regular voltmeter, but you should see some small AC voltage when the engine is cranking. This connection provide a pulse that tells the CDI when dump all that power it has been storing up from the AC ignition power connection onto the ignition coil primary.

Both of these connections should also read resistance to engine ground. Go to the ohmmeter scale and measure the resistance to ground for both those windings at the CDI connector. The AC power widing should be 500 ohms or so (which is the same as 0.500 KiloOhms). The Trigger winding whould read 150 ohms or so. While you are measuring resistances make sure the ground wire(s) in the wiring harness are really connected to engine ground (zero ohms).

Ther are more things that can be measured. This should get you started. Electrics are not difficult with a voltmeter, a little common sense, and some practice. Report back what you measure and we'll go from there.

#6

ok I got the quad to start sparking again, by replacing the coil. Put a new coil on the bike and it ran for about thirty minutes and then back to old tricks again. Anybody know what would cause this bike to burn up coils this fast? All I could think is maybe a voltage regulator, the coil sits about 3" from the exhaust and maybe getting a little hot but I don't think that is it.

#7

Sanford

Does you quad start-up again once the coil cools down?

That will be a good indication that its to close to the exhaust.

Another possibility is your rectifier. Most quad come with a rectifier rather that a voltage regulator.

A rectifier is an electrical device that converts alternating current (AC) to direct current (DC).

Does you quad start-up again once the coil cools down?

That will be a good indication that its to close to the exhaust.

Another possibility is your rectifier. Most quad come with a rectifier rather that a voltage regulator.

A rectifier is an electrical device that converts alternating current (AC) to direct current (DC).

Trending Topics

#8

Join Date: Dec 2008

Location: Tracy, California, USA

Posts: 3,260

Likes: 0

Received 12 Likes

on

12 Posts

<div class="FTQUOTE"><begin quote>Originally posted by: SanfordandSonrepairs

ok I got the quad to start sparking again, by replacing the coil. Put a new coil on the bike and it ran for about thirty minutes and then back to old tricks again. Anybody know what would cause this bike to burn up coils this fast?...</end quote></div>

Umm, this thread started out with the bike running for 20 minutes and then no spark. Now we have progressed to the bike running for 30 minutes and then no spark. That's not a significant change to me. I don't think there is anything wrong with your coils. I might be wrong, but the odds of two coils doing exactly the same thing are long at best.

<div class="FTQUOTE"><begin quote>Originally posted by: SanfordandSonrepairs

...All I could think is maybe a voltage regulator...</end quote></div>

Most ignition systems run on a separate high voltage AC power supply which comes from your stator. This is completely separate from the battery charging circuitry which includes the voltage rectifier/regulator. Therefore the voltage regulator/rectifier isn't involved. Even if you ignition is powered off 12 VDC (not the most common, but becoming more so) you could remove the voltage regulator and the engine will continue to run off the battery.

ok I got the quad to start sparking again, by replacing the coil. Put a new coil on the bike and it ran for about thirty minutes and then back to old tricks again. Anybody know what would cause this bike to burn up coils this fast?...</end quote></div>

Umm, this thread started out with the bike running for 20 minutes and then no spark. Now we have progressed to the bike running for 30 minutes and then no spark. That's not a significant change to me. I don't think there is anything wrong with your coils. I might be wrong, but the odds of two coils doing exactly the same thing are long at best.

<div class="FTQUOTE"><begin quote>Originally posted by: SanfordandSonrepairs

...All I could think is maybe a voltage regulator...</end quote></div>

Most ignition systems run on a separate high voltage AC power supply which comes from your stator. This is completely separate from the battery charging circuitry which includes the voltage rectifier/regulator. Therefore the voltage regulator/rectifier isn't involved. Even if you ignition is powered off 12 VDC (not the most common, but becoming more so) you could remove the voltage regulator and the engine will continue to run off the battery.

#10

Did you remove the kill switch wire out of the harness right at the CDI? There are often three kill switch connections throughout the harness, any one of which can kill the engine. The best way to eliminate them all at once is by disconnecting the kill connection at the CDI.

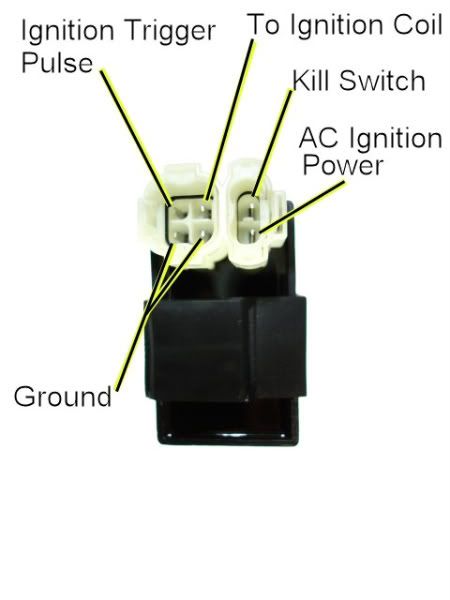

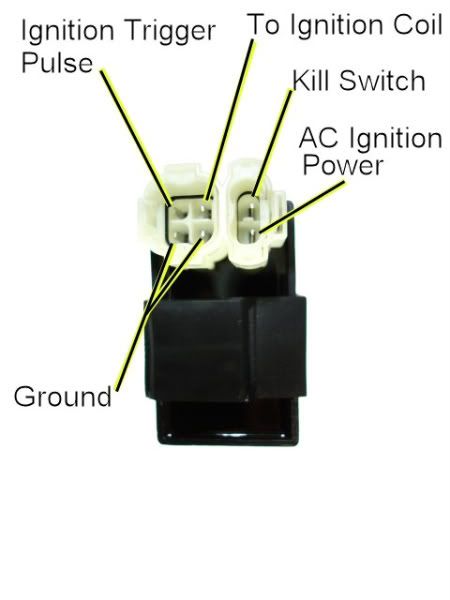

Is this your CDI?

If this is your CDI you can see the connection that must be disconnected to eliminate all the kill switches.

You can measure the stator ignition windings for proper operation without having to take the flywheel off. There are two windings: AC Ignition Power and Ignition Trigger. (There is another winding in the stator is used to charge the battery which I will ignore in this post since it has nothing to do with spark.)

Disconnect the CDI. Use a voltmeter to measure the AC ignition power connection in the wiring harness to engine ground while cranking. It should be 80 volts AC or so. Be sure you measure this on your voltmeter AC scale and not DC. This winding in the stator provides power to run the CDI, ignition coil, and spark. If it isn't putting out voltage then the ignition system won't work. Also, do not measure this voltage with the CDI hooked up. It won't hurt anything, but you will get meaningless results.

Next measure the voltage on the ignition trigger wire voltage to engine ground. It should be 0.1 to 0.4 volts AC while cranking. This is actually a complex waveform that doesn't measure well with a regular voltmeter, but you should see some small AC voltage when the engine is cranking. This connection provide a pulse that tells the CDI when dump all that power it has been storing up from the AC ignition power connection onto the ignition coil primary.

Both of these connections should also read resistance to engine ground. Go to the ohmmeter scale and measure the resistance to ground for both those windings at the CDI connector. The AC power widing should be 500 ohms or so (which is the same as 0.500 KiloOhms). The Trigger winding whould read 150 ohms or so. While you are measuring resistances make sure the ground wire(s) in the wiring harness are really connected to engine ground (zero ohms).

Ther are more things that can be measured. This should get you started. Electrics are not difficult with a voltmeter, a little common sense, and some practice. Report back what you measure and we'll go from there.

Is this your CDI?

If this is your CDI you can see the connection that must be disconnected to eliminate all the kill switches.

You can measure the stator ignition windings for proper operation without having to take the flywheel off. There are two windings: AC Ignition Power and Ignition Trigger. (There is another winding in the stator is used to charge the battery which I will ignore in this post since it has nothing to do with spark.)

Disconnect the CDI. Use a voltmeter to measure the AC ignition power connection in the wiring harness to engine ground while cranking. It should be 80 volts AC or so. Be sure you measure this on your voltmeter AC scale and not DC. This winding in the stator provides power to run the CDI, ignition coil, and spark. If it isn't putting out voltage then the ignition system won't work. Also, do not measure this voltage with the CDI hooked up. It won't hurt anything, but you will get meaningless results.

Next measure the voltage on the ignition trigger wire voltage to engine ground. It should be 0.1 to 0.4 volts AC while cranking. This is actually a complex waveform that doesn't measure well with a regular voltmeter, but you should see some small AC voltage when the engine is cranking. This connection provide a pulse that tells the CDI when dump all that power it has been storing up from the AC ignition power connection onto the ignition coil primary.

Both of these connections should also read resistance to engine ground. Go to the ohmmeter scale and measure the resistance to ground for both those windings at the CDI connector. The AC power widing should be 500 ohms or so (which is the same as 0.500 KiloOhms). The Trigger winding whould read 150 ohms or so. While you are measuring resistances make sure the ground wire(s) in the wiring harness are really connected to engine ground (zero ohms).

Ther are more things that can be measured. This should get you started. Electrics are not difficult with a voltmeter, a little common sense, and some practice. Report back what you measure and we'll go from there.

Thread

Thread Starter

Forum

Replies

Last Post

Frisky2050

Buying an ATV

10

04-09-2020 11:19 AM

ATVC Correspondent

Technical and How-To Articles

0

07-02-2015 01:34 AM

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)