Ask the Editors: Should I Regenerate my ATV Battery?

Obviously the expense of regenerating an ATV battery is about 1/2 the cost of replacement. What tests or factual documentation supports a prolonged life for a used battery as opposed to a new replacement? Jaster94

In the near future as lithium ion battery packs and other similar means of getting voltage to our ATVs becomes more widely accepted, much of the concept of regenerating an older battery will become moot. As it stands, however, there is some solid science behind the concept and here’s why: Lead acid batteries rarely live to their potential lifespan and the reason has all to do with lead-sulfur deposits.

From the moment a lead acid battery is produced, even before its charged for the first time, it begins to create sulphate deposits. The normal operation of cycling (which is to say charging and discharging) the battery results in additional sulphates building up on the plates inside. After each charge, a small number of these sulphates are left behind and over time these deposits build up to the point where they no longer allow the battery to accept a full charge thanks to the all of the resistance they create on the plate surface.

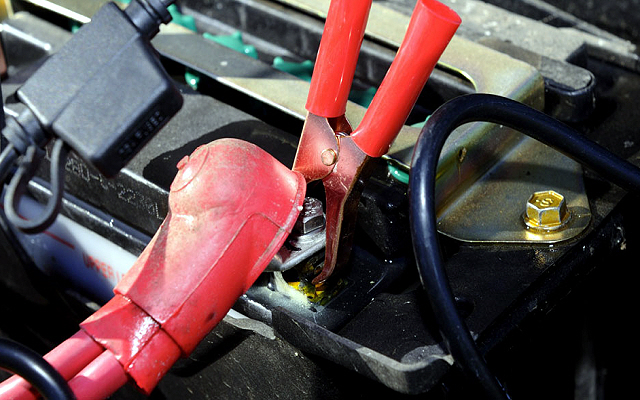

Normally when this happens, we accept that the battery no longer charges, kick it to the curb and simply buy a new one. It doesn’t take a rocket scientist to realize though that if you could simply remove those sulfate deposits clinging to the plates, you’d still have a perfectly functioning battery. Enter the battery regenerator (also called a desulphator, reconditioner or pulse conditioning device). What it does is it restores capacity cycles to a battery by sending high-frequency pulses of electrical current through the battery, causing that sulphate buildup to flake off the plates and eventually dissolve.

Once your old battery has plates as clean as the day it left the factory, it is usually free to cycle hundreds, sometimes even thousands of times before requiring another plate cleaning.

Whether or not this is a wise move for you depends entirely upon cost and convenience. If you or someone you know owns a regenerator, it is a no-brainer as the potential to keep cleaning your battery plates to near factory-level exists each time you run it through. About the biggest disadvantage to battery regeneration is time. It can take several days for a proper plate reconditioning (quicker with a commercial unit like the one shown above) to complete and with the cost of traditional batteries, especially through big box store distributors, having really come down in recent years, oftentimes many of us feel that simply picking up a new battery is more convenient than the hassle of screwing around with the old one.

If you’re interested in learning more about the science behind the process, click here. Many studies on the effectiveness of regeneration have been conducted but none that we’re aware of on so small and dedicated a sample as on a single ATV battery for example. However if you are interested in checking out some of the results of large business use (in this case a client with 1000 weakened forklift batteries), click here.