ATV Tech: Top 5 Mechanical Tips and Tricks

Spring is in the air and while the rest of the world may be thinking about walks on the beach, drinks by the pool or firing up the ol barbecue, your ATV Connection editors are, like always, contemplating ways to make long-neglected ATV maintenance a tad bit less painful.

The following are 5 tips of the trade we’ve picked up from years of spinning wrenches that can make all the difference between a job well done and a trip to the automotive parts store in effort to secure a Helicoil before they close on a Tuesday night.

Start Sharp

If there’s one tip everyone seems to neglect when attempting to work on an ATV that has had a few seasons of abuse under its belt is to start with the sharpest screwdriver tips as possible. To the point where you shouldn’t hesitate to stop at a store and purchase a brand new Phillips head screwdriver before beginning on any project if there’s even the slightest patina of rust or corrosion on the screw head in question. The reason? You are much less likely to round out soft metal with a sharp screwdriver tip when compared to a dull, worn one. This is especially common when working on carburetor screws.

Call Upon the Blaster

When it comes to the art of removing rusty nuts and bolts, brain before brawn- in this case pick up a can of PB Blaster or similar such penetrating lubricant. It works in two ways- first it penetrates the threads and lubes them up so that less torque is required to get them spinning freely. Secondly it starts dissolving rust and other common types of metal corrosion. Often the mistake is starting out with a wrench and deciding to go the way of the penetrating oil only after we’ve encountered a tricky nut or bolt that refuses to let go. Do it the smart way and soak all of the bolts you intend to remove a good 20-mimutes before starting the project. Go in and have a sandwich if you’re the impatient type. You will save yourself untold toil and frustration in the long run in the form of nuts and bolts that turn as if your machine had just left the factory.

Think Ahead for Next Time

Ever try working on a machine caked up with dried mud and swamp detritus? Or worst still, give it a washing just beforehand so you don’t have to deal with such things only to find mud and water in all of the tight spots and crevices? You can counter this frustration by thinking ahead before you go out and get your machine muddied up. Spray everything down with a good coat of WD-40 before you go out for your ride. Frame members, linkages, casings and the plastic itself. The quickly-drying formula will leave behind a shiny film that mud will find very difficult to adhere to. Then after your ride, simply hose the machine off before putting it away and watch as nearly every spec of mud that did find its way onto the surfaces runs down without a trace.

Degrease for Clues

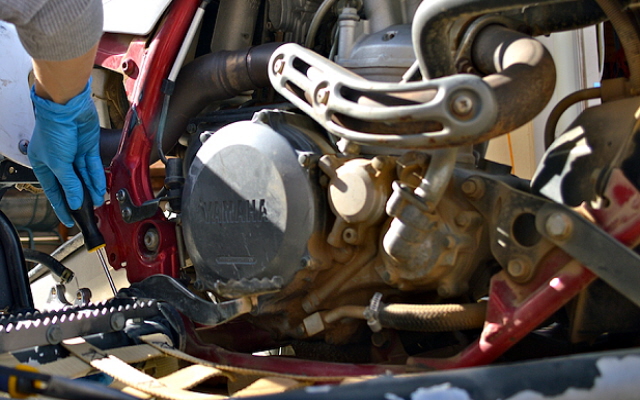

Ever move your quad from its resting spot and find a troubling spot of oil where it previously resided? Our first instinct is to reach up under the frame or take a flashlight and look- to determine where the oil is coming from. Trouble is, fluid mixed with gravity is a good way for oil to make like a creek and flow downward. Oftentimes where it’s gathered up or dripping from isn’t at all where it’s starting. The secret to avoiding unnecessary headaches with this one is to grab a bottle of engine degreaser (we usually like Simple Green around here) and spray the entire engine down. Then rinse away the degreaser with a hose once its dried. Starting with a clean engine will make tracing the origins of an oil leak exponentially easier.

Right Tool for the Job

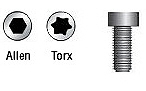

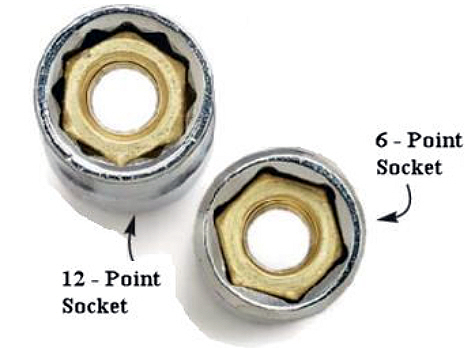

If, even after having followed all of the above tips, you encounter a bolt or nut that refuses to budge, set down the open-end/ box wrench and grab a socket. Tap the ratchet with the side of a hammer or rubber mallet. If that still doesn’t provide adequate torque to loosen things up, head back to the toolbox (or auto parts store if you don’t have one handy) and try a hexagonal (6-point) socket instead of the more common 12-point. Why does that matter? 12-pointers are popular because they grab a bolt by more points and thus turn them faster (which is of course beneficial for removing bolts in tight spaces). But with ATVs, room is rarely the issue; and half the grip points offers more leverage to each of them. Also a 12-point grips a bolt at its edges while a 6-point grips it on the flat spots in between.

Finally, and along these same lines, just because it occasionally works, never take the easy way out and use an allen wrench to turn a torx bit or vice-versa either. This is a good way to damage the bit and make removing it later next to impossible.