Royal Purple

| Royal Purple

All oils are not created |

|

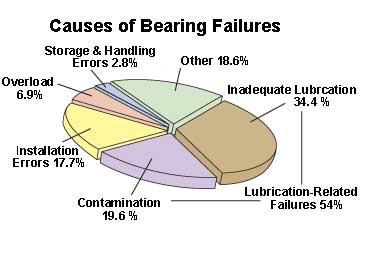

Oil is not something we think of as a performance enhancer, unless you’re serious about maintaining a strong engine with long lasting performance. Royal Purple is a company that strives to produce lubricants that provide the highest level of performance possible. Because Royal Purple’s sole focus is to create state-of-the-art lubricants that are of the highest quality their developers can produce. All oils are not created equally, there are so many variables. As with everything else in this world, when it comes to lubricant you get what you pay for, expensive oils produce better results. A performance oil should have good film strength or the ability to build up on parts, be well filtered and hold up to heat. Film strength is a lubricant property that acts to prevent scuffing or scoring of metal parts. Film strength is measured by the American Society for Testing Materials’ (ASTM) Timken OK Load test, which measures the heaviest load that a lubricant will sustain without scoring the test block. Royal Purple’s film strength is up to 400 percent stronger than other synthetics, which greatly reduces wear and extends equipment life. Royal Purple has the ability to outperform leading synthetic-based and mineral-based oils. The secret is Synerlec®, part of Royal Purple’s entire line of products. Synerlec® is Royal Purple’s proprietary, lubricant additive technology that strengthens the oil film to provide extra protection and performance. Synerlec® continuously adheres to metal parts, even after shutdown. The thin film of oil that remains after shutdown preserves parts and provides instant lubrication at start-up until a full fluid oil film can be established. Our testing indicated that cold weather starts became easier with the Royal Purple oils. The primary purpose of any lubricant is to reduce friction. The lubrication reductions friction and can increase equipment performance and extend engine life.

Purple is a company that strives to produce lubricants that provide the highest level of performance possible. Because Royal Purple’s sole focus is to create state-of-the-art lubricants that are of the highest quality their developers can produce. All oils are not created equally, there are so many variables. As with everything else in this world, when it comes to lubricant you get what you pay for, expensive oils produce better results. A performance oil should have good film strength or the ability to build up on parts, be well filtered and hold up to heat. Film strength is a lubricant property that acts to prevent scuffing or scoring of metal parts. Film strength is measured by the American Society for Testing Materials’ (ASTM) Timken OK Load test, which measures the heaviest load that a lubricant will sustain without scoring the test block. Royal Purple’s film strength is up to 400 percent stronger than other synthetics, which greatly reduces wear and extends equipment life. Royal Purple has the ability to outperform leading synthetic-based and mineral-based oils. The secret is Synerlec®, part of Royal Purple’s entire line of products. Synerlec® is Royal Purple’s proprietary, lubricant additive technology that strengthens the oil film to provide extra protection and performance. Synerlec® continuously adheres to metal parts, even after shutdown. The thin film of oil that remains after shutdown preserves parts and provides instant lubrication at start-up until a full fluid oil film can be established. Our testing indicated that cold weather starts became easier with the Royal Purple oils. The primary purpose of any lubricant is to reduce friction. The lubrication reductions friction and can increase equipment performance and extend engine life.

Purple is a company that strives to produce lubricants that provide the highest level of performance possible. Because Royal Purple’s sole focus is to create state-of-the-art lubricants that are of the highest quality their developers can produce. All oils are not created equally, there are so many variables. As with everything else in this world, when it comes to lubricant you get what you pay for, expensive oils produce better results. A performance oil should have good film strength or the ability to build up on parts, be well filtered and hold up to heat. Film strength is a lubricant property that acts to prevent scuffing or scoring of metal parts. Film strength is measured by the American Society for Testing Materials’ (ASTM) Timken OK Load test, which measures the heaviest load that a lubricant will sustain without scoring the test block. Royal Purple’s film strength is up to 400 percent stronger than other synthetics, which greatly reduces wear and extends equipment life. Royal Purple has the ability to outperform leading synthetic-based and mineral-based oils. The secret is Synerlec®, part of Royal Purple’s entire line of products. Synerlec® is Royal Purple’s proprietary, lubricant additive technology that strengthens the oil film to provide extra protection and performance. Synerlec® continuously adheres to metal parts, even after shutdown. The thin film of oil that remains after shutdown preserves parts and provides instant lubrication at start-up until a full fluid oil film can be established. Our testing indicated that cold weather starts became easier with the Royal Purple oils. The primary purpose of any lubricant is to reduce friction. The lubrication reductions friction and can increase equipment performance and extend engine life.

Purple is a company that strives to produce lubricants that provide the highest level of performance possible. Because Royal Purple’s sole focus is to create state-of-the-art lubricants that are of the highest quality their developers can produce. All oils are not created equally, there are so many variables. As with everything else in this world, when it comes to lubricant you get what you pay for, expensive oils produce better results. A performance oil should have good film strength or the ability to build up on parts, be well filtered and hold up to heat. Film strength is a lubricant property that acts to prevent scuffing or scoring of metal parts. Film strength is measured by the American Society for Testing Materials’ (ASTM) Timken OK Load test, which measures the heaviest load that a lubricant will sustain without scoring the test block. Royal Purple’s film strength is up to 400 percent stronger than other synthetics, which greatly reduces wear and extends equipment life. Royal Purple has the ability to outperform leading synthetic-based and mineral-based oils. The secret is Synerlec®, part of Royal Purple’s entire line of products. Synerlec® is Royal Purple’s proprietary, lubricant additive technology that strengthens the oil film to provide extra protection and performance. Synerlec® continuously adheres to metal parts, even after shutdown. The thin film of oil that remains after shutdown preserves parts and provides instant lubrication at start-up until a full fluid oil film can be established. Our testing indicated that cold weather starts became easier with the Royal Purple oils. The primary purpose of any lubricant is to reduce friction. The lubrication reductions friction and can increase equipment performance and extend engine life.  |

|

|

Royal Purple micro-polishes asperities which are irregularities on bearing surfaces, using Royal Purple can reduce friction and smooth the bearing surface creating less friction and improving durability. Many lubricants have a short service life because they lack oxidation stability. Oxidation causes increased viscosity and oxidized oil deposits. A product’s ability to resist oxidation is measured by the ASTM’s Turbine Oil Stability Test (TOST) and Dry Air Oxidation test and the ASTM’s Thin Film Oxidation Uptake Test (TFOUT). Royal Purple not only surpasses leading mineral-based and synthetic-based oils in these tests but also outlasts the duration of the TFOUT test. Royal Purple’s superior oxidation stability and its ability to clean deposits left by previous oils can results in fewer oil changes, saving time, money and the environment. Royal Purple lubricants are filtered to produce a clean product with better quality. Royal Purple’s lubricants are packaged in new, clean poly drums, pails and bottles to ensure that product cleanliness is maintained from blend to delivery. Couple this with Royal Purple’s state-of-the-art precision blends, and you’ll always receive the same, dependable product each and every time. Using Royal Purple should make an immediate difference, helping to keep your engines running for a long time. Equipment reliability should increase and produce reductions in energy and maintenance costs. The ATV Connection now uses Royal Purple products and plans on making Royal Purple Products the Official ATV Connection lubricant of choice. Check back with us as we continuously update our long term evaluation of the Royal Purple products. We are interested in long term durability, heat and viscosity loss and any other findings we encounter along the way.

Dry Air Oxidation test and the ASTM’s Thin Film Oxidation Uptake Test (TFOUT). Royal Purple not only surpasses leading mineral-based and synthetic-based oils in these tests but also outlasts the duration of the TFOUT test. Royal Purple’s superior oxidation stability and its ability to clean deposits left by previous oils can results in fewer oil changes, saving time, money and the environment. Royal Purple lubricants are filtered to produce a clean product with better quality. Royal Purple’s lubricants are packaged in new, clean poly drums, pails and bottles to ensure that product cleanliness is maintained from blend to delivery. Couple this with Royal Purple’s state-of-the-art precision blends, and you’ll always receive the same, dependable product each and every time. Using Royal Purple should make an immediate difference, helping to keep your engines running for a long time. Equipment reliability should increase and produce reductions in energy and maintenance costs. The ATV Connection now uses Royal Purple products and plans on making Royal Purple Products the Official ATV Connection lubricant of choice. Check back with us as we continuously update our long term evaluation of the Royal Purple products. We are interested in long term durability, heat and viscosity loss and any other findings we encounter along the way.

Dry Air Oxidation test and the ASTM’s Thin Film Oxidation Uptake Test (TFOUT). Royal Purple not only surpasses leading mineral-based and synthetic-based oils in these tests but also outlasts the duration of the TFOUT test. Royal Purple’s superior oxidation stability and its ability to clean deposits left by previous oils can results in fewer oil changes, saving time, money and the environment. Royal Purple lubricants are filtered to produce a clean product with better quality. Royal Purple’s lubricants are packaged in new, clean poly drums, pails and bottles to ensure that product cleanliness is maintained from blend to delivery. Couple this with Royal Purple’s state-of-the-art precision blends, and you’ll always receive the same, dependable product each and every time. Using Royal Purple should make an immediate difference, helping to keep your engines running for a long time. Equipment reliability should increase and produce reductions in energy and maintenance costs. The ATV Connection now uses Royal Purple products and plans on making Royal Purple Products the Official ATV Connection lubricant of choice. Check back with us as we continuously update our long term evaluation of the Royal Purple products. We are interested in long term durability, heat and viscosity loss and any other findings we encounter along the way.

Dry Air Oxidation test and the ASTM’s Thin Film Oxidation Uptake Test (TFOUT). Royal Purple not only surpasses leading mineral-based and synthetic-based oils in these tests but also outlasts the duration of the TFOUT test. Royal Purple’s superior oxidation stability and its ability to clean deposits left by previous oils can results in fewer oil changes, saving time, money and the environment. Royal Purple lubricants are filtered to produce a clean product with better quality. Royal Purple’s lubricants are packaged in new, clean poly drums, pails and bottles to ensure that product cleanliness is maintained from blend to delivery. Couple this with Royal Purple’s state-of-the-art precision blends, and you’ll always receive the same, dependable product each and every time. Using Royal Purple should make an immediate difference, helping to keep your engines running for a long time. Equipment reliability should increase and produce reductions in energy and maintenance costs. The ATV Connection now uses Royal Purple products and plans on making Royal Purple Products the Official ATV Connection lubricant of choice. Check back with us as we continuously update our long term evaluation of the Royal Purple products. We are interested in long term durability, heat and viscosity loss and any other findings we encounter along the way.