The Under-Appreciated Oil Filter

By Jason Giacchino

By Jason Giacchino

You’ve probably already surmised that the function of your ATV’s oil filter is to filter out particulates in your motor’s oil but just how does a simple paper element hold up to the extreme conditions found within a high-performance engine? Read on to find out.

Rock, Paper, Scissors

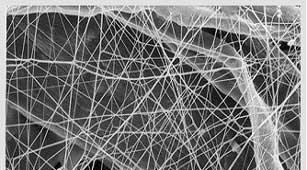

While there have been success stories in using metal screen filtration systems (brass and stainless steel), the vast majority of ATV oil filters use simple paper elements because they work. They begin life as cellulose (fiber) paper, which appears smooth to the naked eye but is actually quite porous under magnification and to a lesser degree, to touch. The material’s naturally spongy nature allows it to permit the passage of liquid (oil) while trapping any solid debris in the process.

Of course if we changed our oil filter before during and after every ride, the cellulose may stand a chance in its paper form alone. However, to compete with the repeated task asked of it within an extremely hot environment, the paper is chemically treated at the factory for durability.

Accordion Style

It’s by no accident that all filters make use of a pleated profile surrounding an inner core (which is usually mesh-type metal). The pleats increase the surface area of filtration by a whopping 211 percent over a smooth cylindrical pattern. More filtration surface area means more trapped particles.

Clogged Pores

Believe it or not, your oil filter begins doing its job the moment it is installed. As oil saturates the filter’s element, invisible to the eye particles begin finding it hard to squeeze through pores in the paper that allow oil to pass freely. This is a good thing as it means the filter is doing what it is supposed to (in keeping these debris out of the engine’s internals). However, with each trapped particle comes slightly less oil flow in the future.

As more and more pores clog up with particulates, less and less oil is able to pass through the filter. Eventually and inevitably, all oil filters reach a point where oil can no longer pass through the filter element itself and is forced through a mechanical bypass that pops open thanks to pressure being supplied by your engine’s oil pump.

If not for the bypass mechanism, a clogged filter would result in engine seizure due to lack of lubrication. However, the bad news in waiting to the point where the bypass is activated means that the oil reaching the engine is no longer being filtered.

No Cleaning Zone

You may have heard the same tales we have of riders soaking their filter in a cleaning formula then reusing it. As much as we understand the desire to save a few bucks in these tough economic times, this is one area where throwing out the old and replacing it with new is essential. Even if you were able to somehow dislodge all of the debris that managed to get jammed in the oil filter element’s pores, those pores would now be stretched terribly out of shape. Yes oil would once again be able to flow through the filter (just like it did when it was new) only now, thanks to pores double and sometimes triple their original size, containments that it should be stopping will now be given full access.

The Bottom Line

Modern four strokes depend on frequent oil changes for survival. Make certain to change the filter at each of these intervals as a fresh element acts as protection against the machine’s bypass mechanism.