A Primer on ATV Charging Systems Page 2

Break-even RPM

One way to gauge if the charging system on an ATV is adequate is to simply turn all standard vehicle electrical loads on high. Then measure where the “Break-even RPM” is. Note: Consult with your dealer to confirm this process on each given model. The following test can only be performed safely on models equipped with pull-start capability. To determine break-even RPM, use a current-measuring device (called an Ammeter) set to DC Amps. Be sure the ammeter is capable of measuring at least 10 Amps and that your battery is well charged. You need to measure how much current is flowing into or out of the battery’s negative post. If current is flowing into the battery the charging system is putting out enough power, if current is flowing out of the battery it is because the charging system isn’t keeping up with the electrical loads. To check this, a couple of safety measures are in order. Disconnect the starter solenoid so that you cannot accidentally turn over the starter motor during the test. Unless you want to put a new doorway in your garage wall, be sure the transmission is in neutral or remove the CVT drive belt.

Connect a tachometer to the ATV. The engine must be off. Put the negative lead of the ammeter onto the negative post of the battery, and the positive lead of the ammeter on the ground wire (s) that were connected to the negative post. Be sure that all ground wires have good contact to each other and do not leave any grounds connected to the battery for this test. Pull-start the ATV. With the ammeter set to its highest DC range, and the standard electrical loads turned on high, look at the ammeter readout. At idle it will almost certainly be negative. If it is positive your test is done—the charging system on your ATV is very capable. If the readout is negative, slowly increase the RPM level until the reading goes positive. A break-even RPM range of just above idle (on a warm engine) to around 2,000 RPM is standard for most magneto charging systems on ATVs. If the RPM must be increased to 2,500 RPM or more, the charging system was poorly designed for the ATV and you will have battery problems if you plan to operate your ATV at low RPM for utility purposes, or if you plan to run high-current accessories. On the other hand, if you usually operate your ATVs at higher RPM in fast trail-riding situations, the break-even RPM may not be much of an issue—as long as you are always sure to keep your battery charged.

How clean is the electrical power on your ATV?

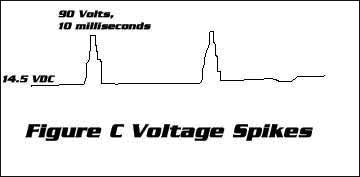

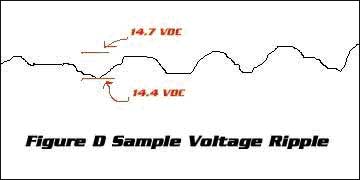

When we talk about clean power, we mean electrical power that is free of excessive electrical “spikes” and “ripple”. A voltage spike is a high peak voltage of short duration and often originates from somewhere out in the vehicle electrical system. (See Fig. C) It can be negative or positive; it can be one time or constantly repeating. Ripple is the standard amount of voltage fluctuation that the regulator itself allows to pass through after it turns the AC from the stator into the DC (See Fig D). If electronic devices like cell phones or stereos are going to be tapped into the ATVs electrical system clean power is a necessity. Noisy power may cause damage or hinder the performance of an electronic device to the point that it is useless. If the only loads on the ATV are lights, ripple is not important—but voltage spikes can blow bulbs in a heartbeat. Read on to learn more.

An ATV pilot would be surprised at how many different forms of electrical noise there are. Transient voltages, inductive spikes, load dumps and switching noise are just some of the noise that electrical engineers have to deal with on today’s quads. For example, any electrical coil such as the coil in a starter solenoid, will send out a nasty voltage spike when power is removed from it, Fan motors turn into generators when power is removed from them, sometimes briefly putting out as much as 30 volts DC!

One very serious cause of noise is when the battery is disconnected from the system. This is known as an “open battery” condition and the designer of an electrical system should design for and test for this commonly occurring problem. The battery acts like a giant filter capacitor on the entire electrical system. The battery provides stability to the electrical system like a flywheel does to the crankshaft of an engine. When the battery is disconnected, especially intermittently, the bus voltage suddenly wants to fluctuate up and down severely. The voltage regulator can and should be designed to keep open battery voltage fluctuations within reasonable limits so electrical parts are not damaged. In my opinion this should be a design requirement on all ATVs, however some brands do not design for this and the owner of that ATV could be in for an expensive bill if one of his battery cables breaks or works loose while in use. At the very least, electronic components such as the speedometer should be designed to turn themselves off without damage if an open battery or other over-voltage situation occurs on the electrical bus. Ask an experienced technician at your dealership how well your ATV will withstand an open battery condition and maintain your ATV accordingly.

The regulator design directly controls how much ripple the DC voltage has, but the regulator cannot minimize or “attenuate” all of the noise on the electrical bus. A lot of noise must be separately attenuated as close to the source of the noise as possible. Electrical accessories that act as simple resistors such as lights and warmers should be okay to add onto any ATV from the standpoint of clean electricity. But be wary of using electronic devices on your ATV. Do your homework and see if other people are already using such devices on the same model as you own before you experiment with anything. A rule of thumb to remember is that ATVs equipped with DC ignitions and/or Electronic Fuel Injection require cleaner voltage than those that have CDI ignitions. Because of this fact it is true that the high-end, big-bore ATVs of today generally have cleaner power than older and lower-cc models do.

Why is there a “Break-Even” RPM at all? Why don’t ATVs just charge the battery at all times regardless of RPM like a car?

The answer to this question is two-fold. First, the 1:1 gear ratio of the crankshaft to the magneto assembly makes it difficult for the magneto to keep up at idle. To design a magneto that has plenty of juice at idle adds cost that most OEMs are unwilling to bear. BRP/Can-Am has tried to correct the “break-even” RPM issue on their recent models and in my opinion, they should be commended for finally attempting to eliminate the problem with charging systems being inadequate at idle.

The second part of the answer is: Unlike car and truck owners ATV consumers have learned to accept battery maintenance. In part this is because they park their machines for months at a time and under such circumstances any wise vehicle owner would charge the battery occasionally—but this is only part of the reason. The other half of battery maintenance is the widely known fact that ATVs are not designed to charge the battery at low RPM. If ATV consumers consistently demanded a charging system that would charge their battery in all riding conditions and with high-current accessories attached, ATV OEMs would eventually buckle to the pressure. ATV riders still accept the fact that they have to pay special attention to battery charging or occasionally buy a new battery. It is possible to eliminate “Break-Even RPM”, but the question is–will consumers pay for it?

Charging system phases—1 for the money, 3 for the Go

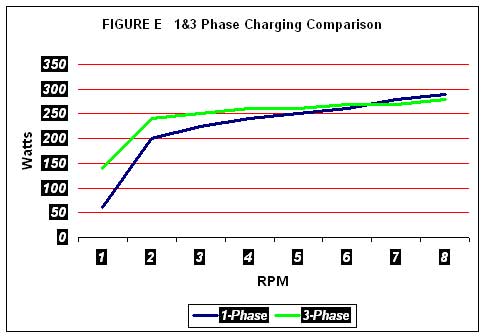

Charging systems used on ATVs come in 2 varieties—single phase and 3-phase. These terms describe how, and the timing of, output power being captured from each charging coil by the voltage regulator. If you intend to use your ATV for a lot of low-RPM, slow-speed operation a 3-phase charging system will generally have a higher charging output at low RPM levels than a single-phase charging system will. A 3-phase stator can be at a slight disadvantage in comparison to a single-phase at high RPM, but it is not usually enough to matter. There is no definite rule on which system is 100% better. Simply understand that if 2 charging systems are rated for the roughly the same watts, a 3-phase system will keep your battery charged better during low RPM running than a single-phase system will (see Figure E). On the other hand, any rider who lets their quad sit unused for more than 1 or 2 months needs to put a charger on their battery regardless of what type of charging system they have. Some manufacturers list how many phases their stator is designed to generate at, some don’t. A quick look at the regulator connection can sometimes help you see. 3-phase systems have 3 AC power wires coming into the regulator, single-phase systems have two. Japanese ATV and motorcycle manufacturers implemented 3-phase charging systems first, but now there are models in every ATV Manufacturer’s stable that have this technology. 3-phase systems cost a little more to regulate but are usually worth it.

When I was developing new charging systems at Polaris and Arctic Cat, I would specify the charging system by listing out all of the anticipated electrical loads, including reasonable accessory use, with each one multiplied by a duty cycle. Then I would add these figures together and add a small safety factor to be sure the battery was always charging. The result was a 3-point charging system specification that dictated the power output required at idle, 2,000 and 4,000 RPM. Since beefier charging systems produce a little more heat, weigh a little more and cost more there were some interesting internal debates about my recommendations. The magneto is part of the engine assembly and the engine design team usually hesitates to implement any changes.

Once when I was at Polaris, I went back and forth with the project leader on a new engine program. He insisted that we should specify a lower-wattage stator already in use on some production models. My calculations showed we needed a stator with about 30% more wattage than that and I pressed the point. During the development of the new engine it had some problems with overheating—no easy thing to fix while still meeting the timelines for program delivery. Someone discovered that they could put a larger cooling fan on to solve the problem. This saved the program from being delayed by possibly a year and some members of the engine development team were heroes. As I recall, no one bothered to connect the dots and see how the extra power available for the bigger fan had come into being…

Voltage regulators

Today’s voltage regulators, also known as rectifier/regulators, rectify the AC output from the stator portion of the magneto assembly to convert it to crude DC. Then they do their best to “level off” the voltage at the specified value so the power is suitable for electrical devices on the system “Bus” and to charge the battery. The operation of a voltage regulator is extremely fast. The regulator adapts to each waveform that is generated by the stator—which is operating at thousands of RPM and has multiple “poles” (usually 6) that each generate 1 sine wave per engine revolution. While operating, most ATVs should have a regulated voltage in the 14.1 to 14.8 volts range unless the voltage is measured in a condition below Break-Even RPM. If the charging system is overburdened, the “Bus” voltage will drop to the voltage level that the battery sustains—usually in the 12+ volt range.

Every ATV Manufacturer has learned through much trial and error about the significance of dealing with heat issues in regulators. The location of some regulators is critical because they use airflow to help them stay cool. Never move a regulator from the location that the OEM placed it in.

Charging Systems—Foundation For Electronic Advancements On ATVs

Charging systems have come a long way on ATVs. As recently as the 1990s charging systems only had average outputs in the 100+ watts range and today many are capable of over 300 watts. As electrical features have increased, so have magneto charging system outputs. Automotive Technologies of all types will inevitably find their way into ATV platforms. Can we finally expect OEMs to treat charging systems and electrical systems in general as being equally important to the drivetrain and suspension? It remains to be seen. One thing is for certain, charging systems are the foundation upon which all future electronic features must be built upon.

Gary Gustafson is the President of G-Force Consulting, a firm that provides consulting for aftermarket and OEM powersports electronics development.