1997 CR80 Project

#11

#12

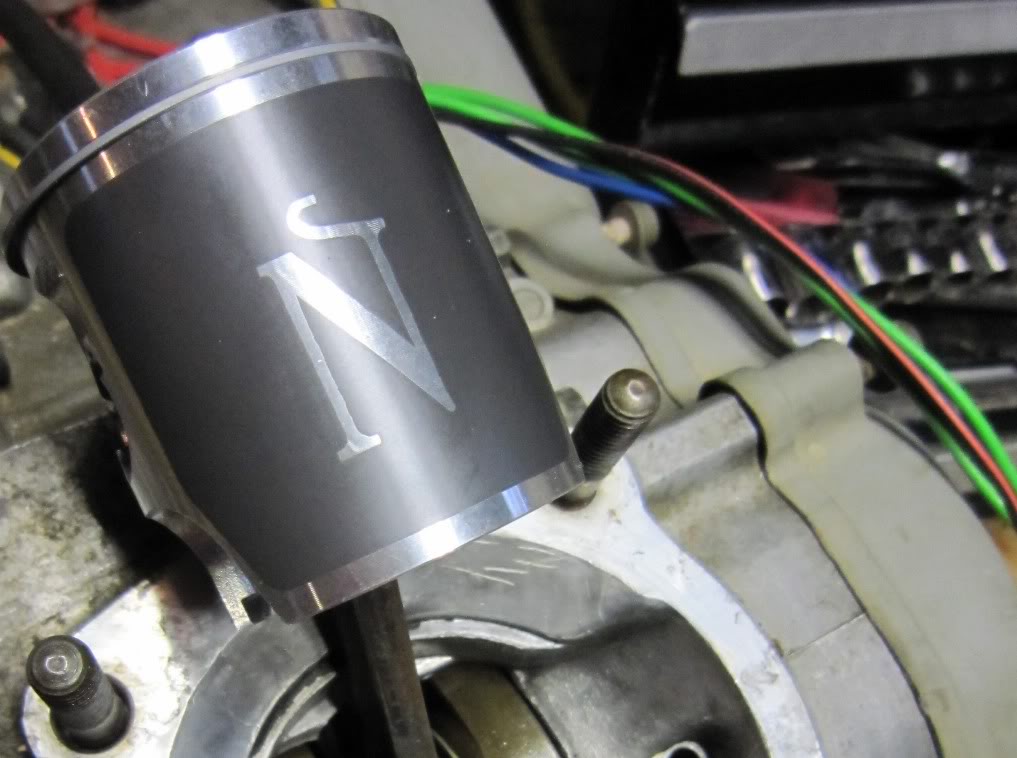

Ya my buddie told me 90% of them are plated from the factory. As far as the piston identification goes I did not have a micrometer on hand today, the piston states "2270G" and under that it says "643M04700". That translates to a Wiseco 47mm, should I hone the fluck out of it with a flex-hone and then use a 47.5mm piston?

My head should be fine right?

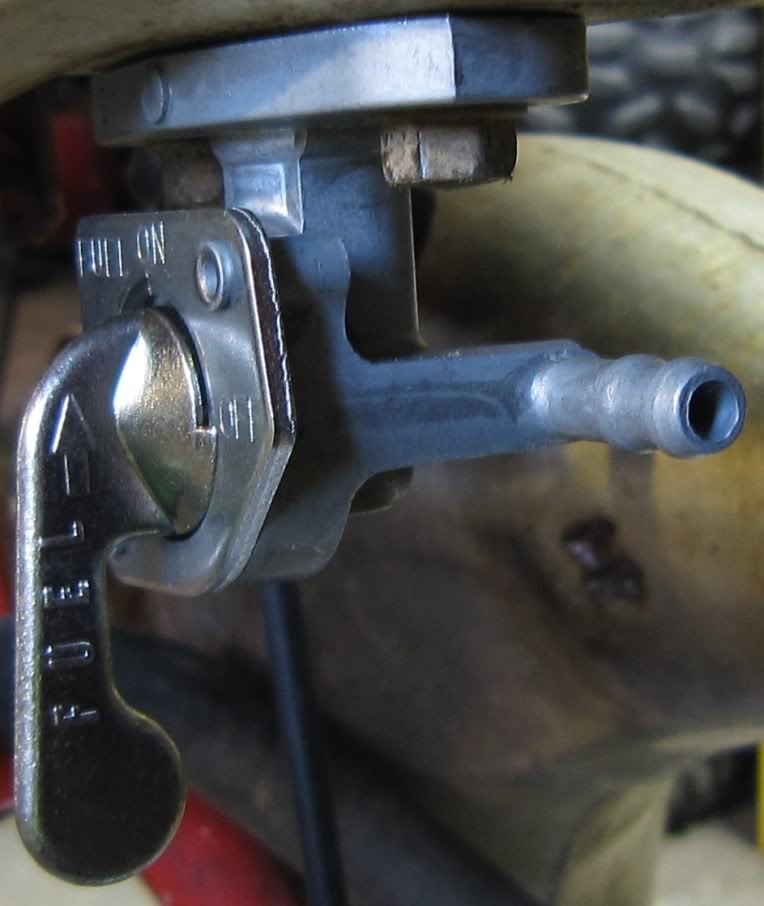

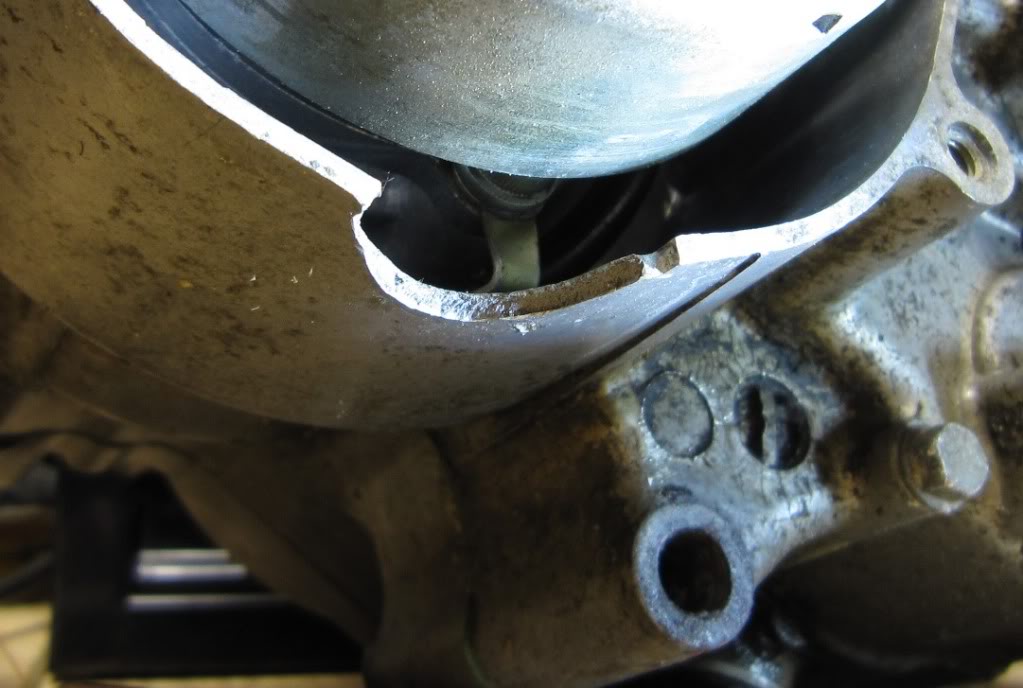

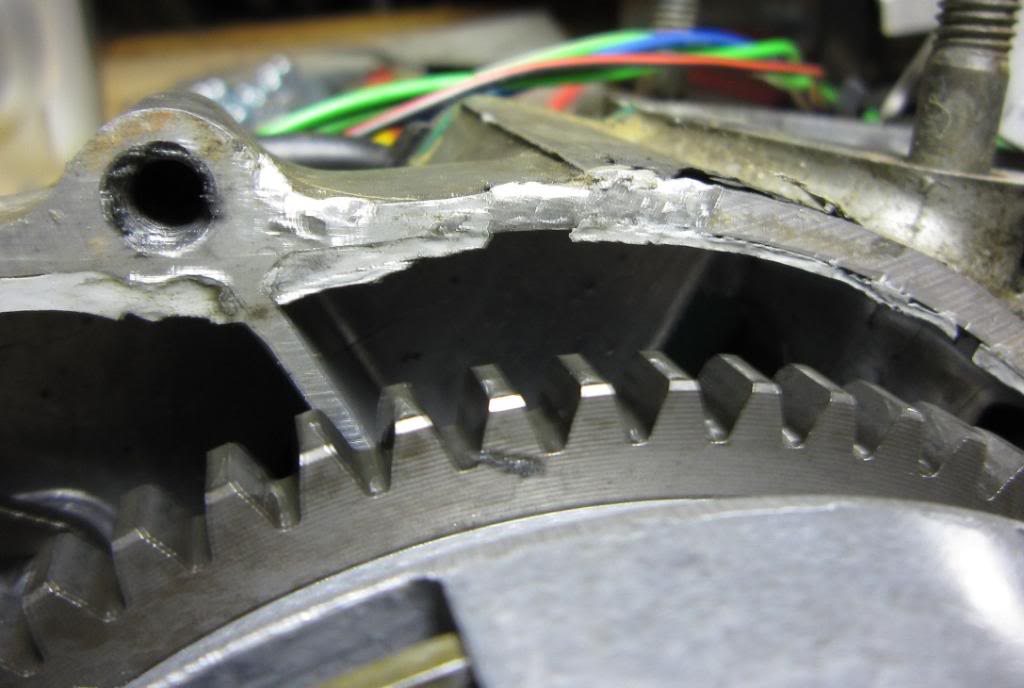

FLUUUUCKER there's a hole in the case under the flywheel, so I called the kid I bought it from and made him give me my $50 back so I got the CR for a $100 bicycle. I'm guessing there is less oil pressure on this side compared to the clutch side (the flywheel cover is plastic) so it could have been worse? I'm going to try and patch this up because there was a patch on my lt230s like this and it's holding fine (maybe some JB weld?)

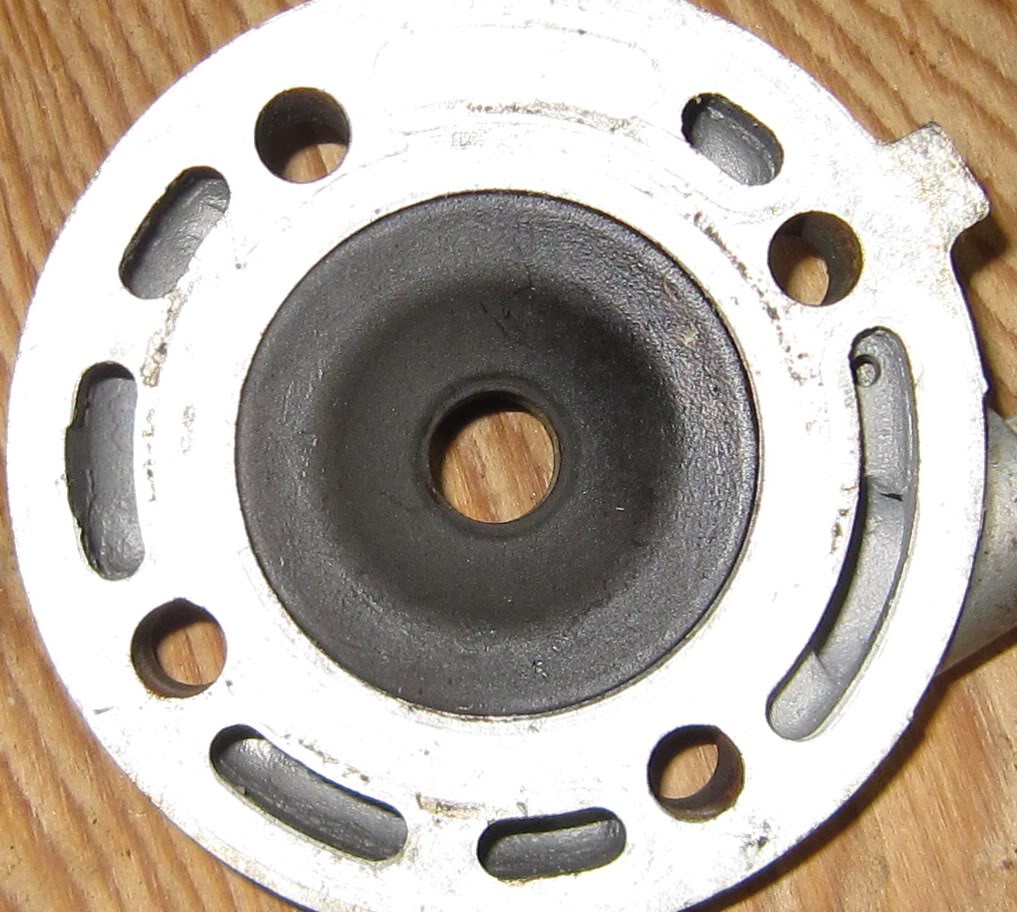

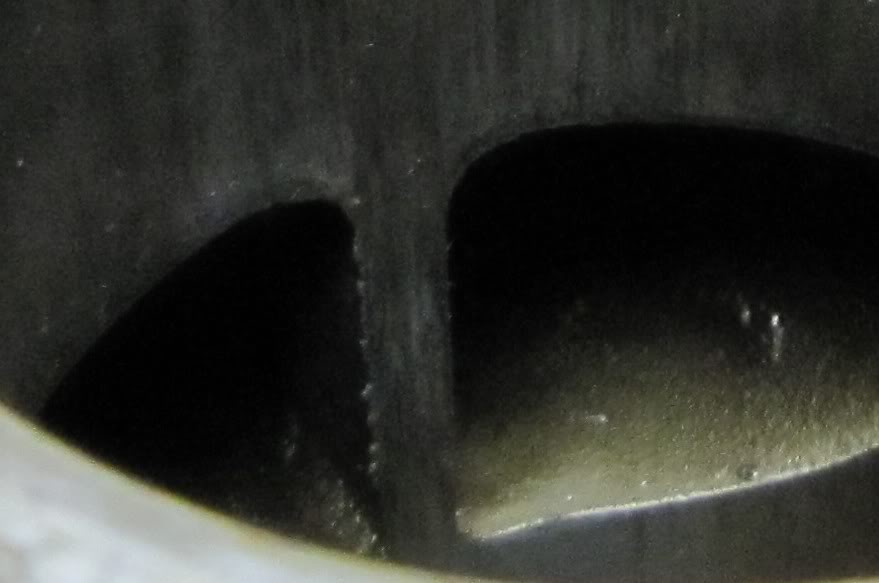

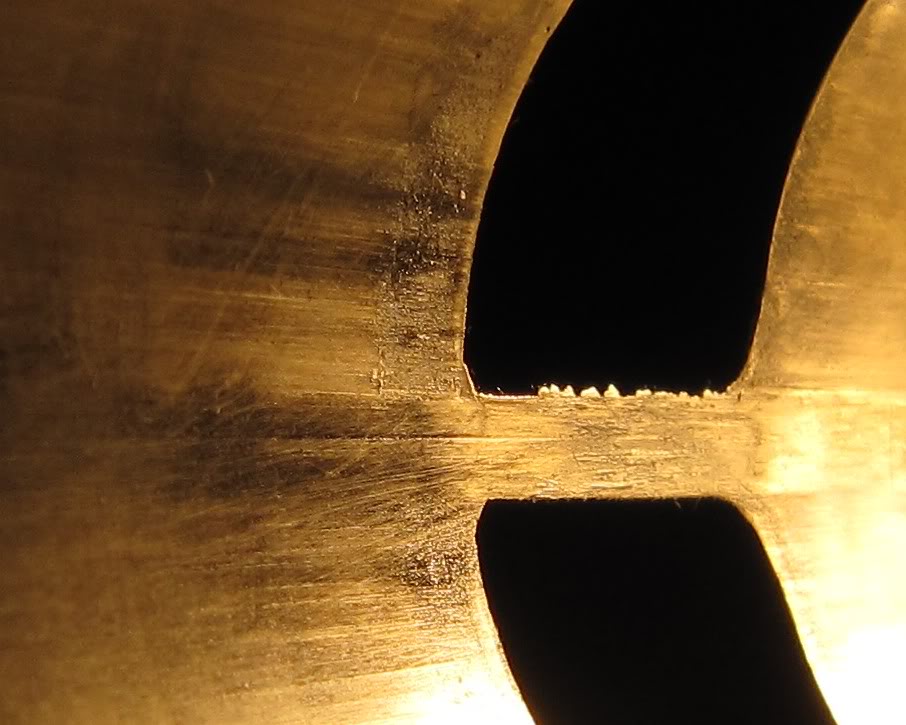

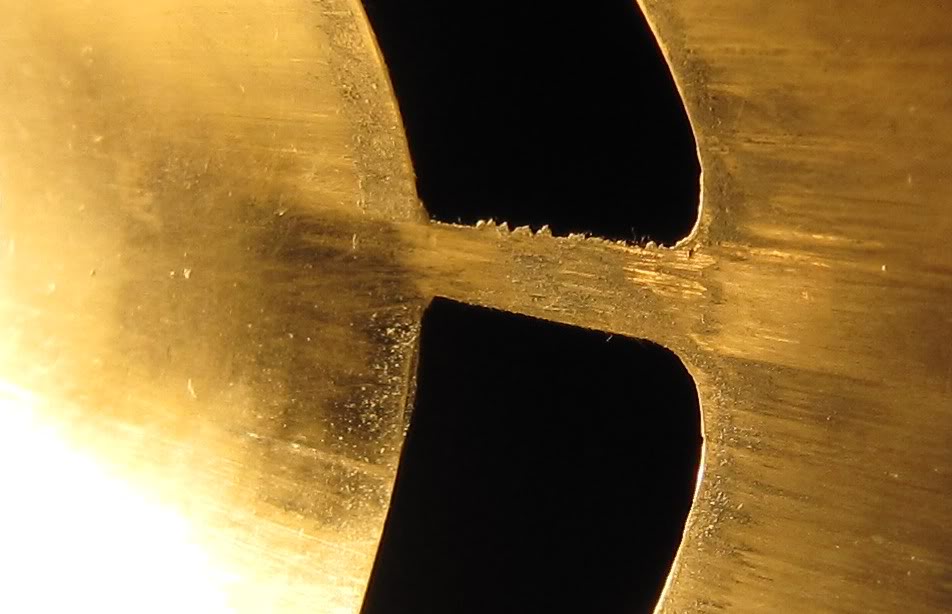

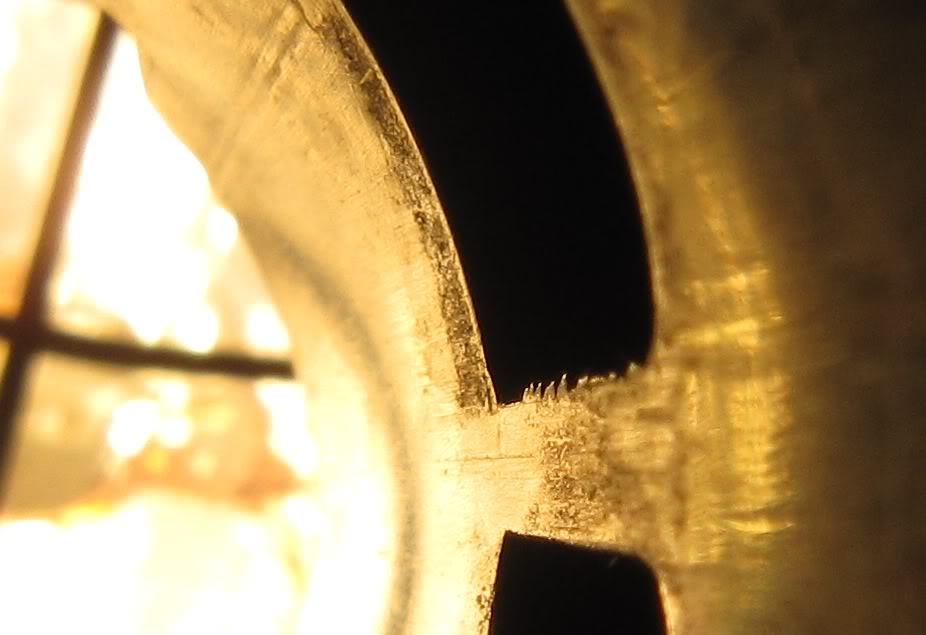

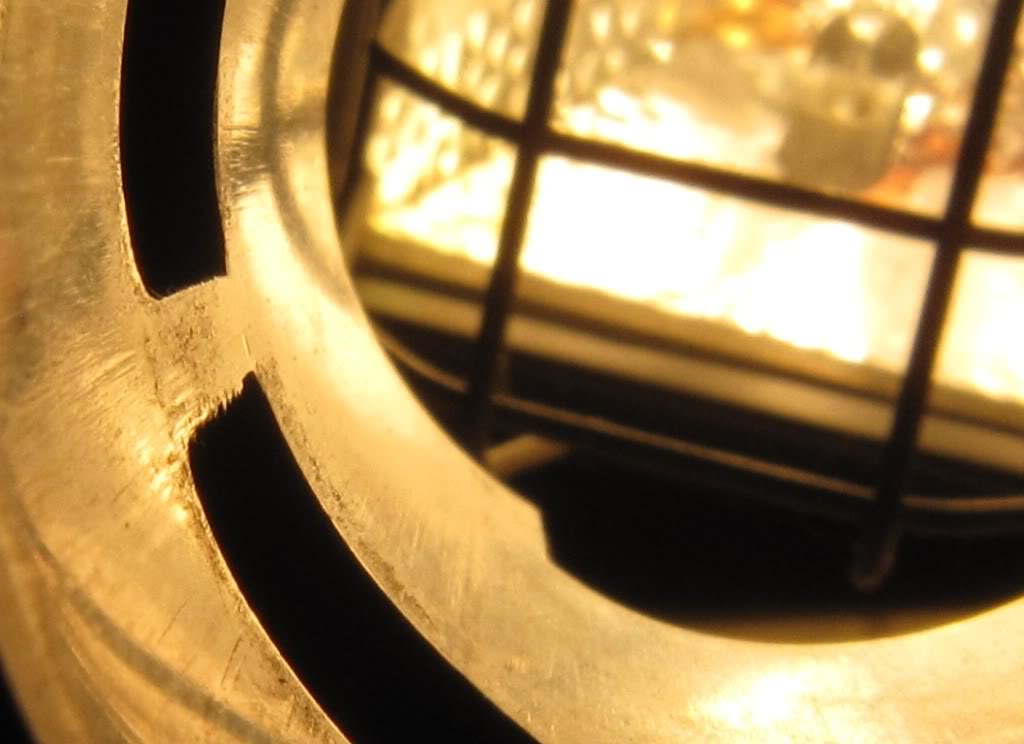

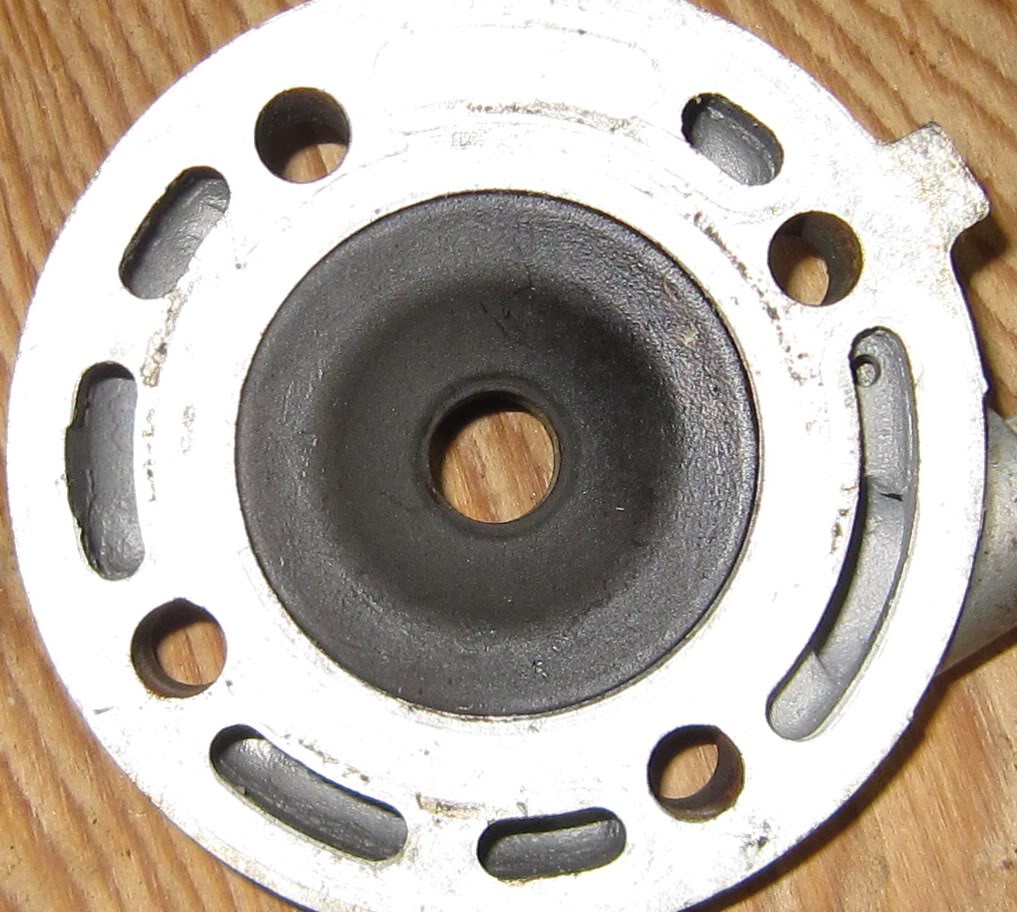

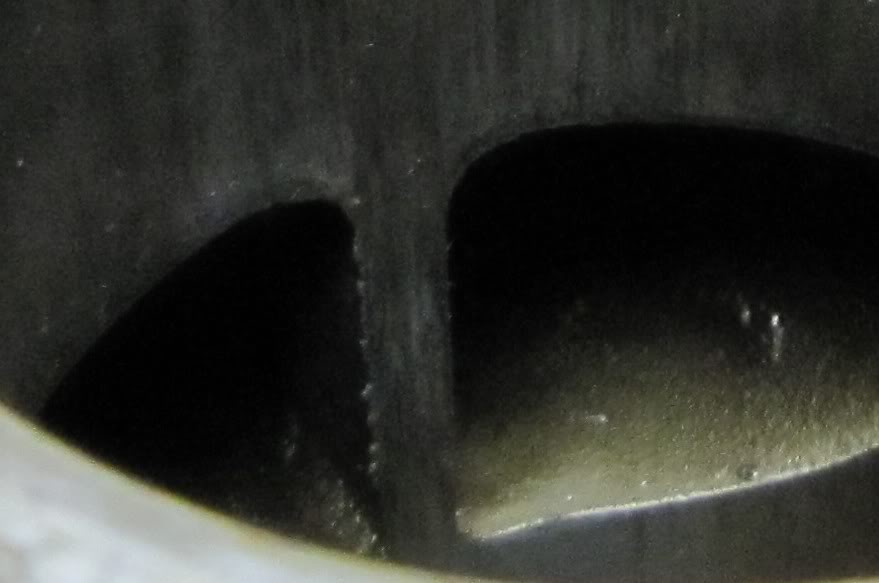

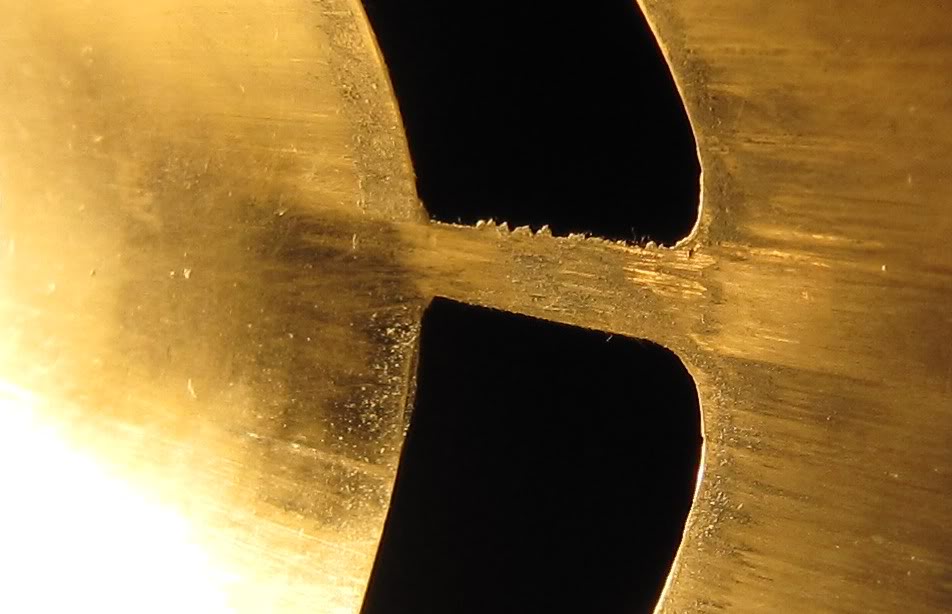

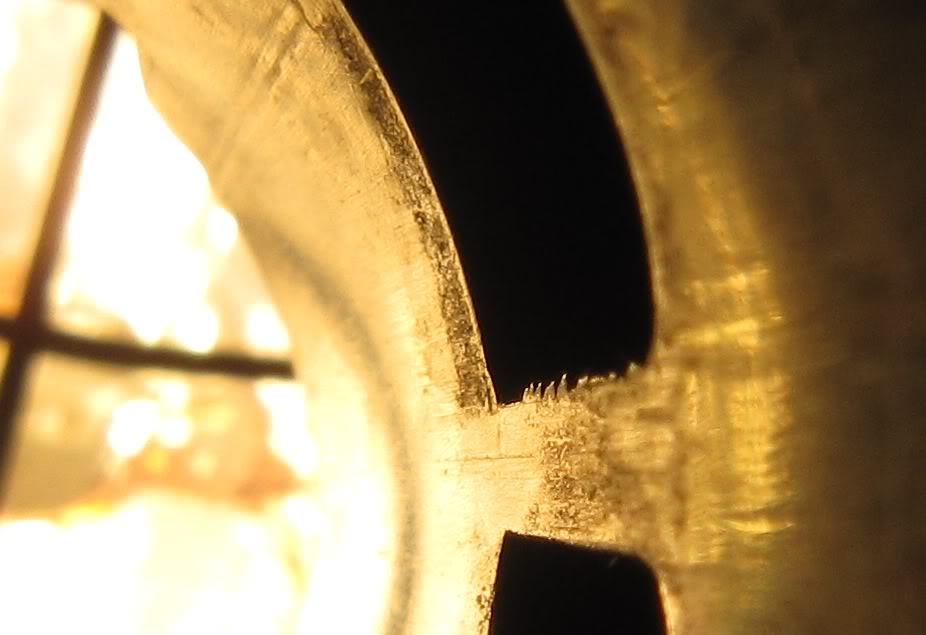

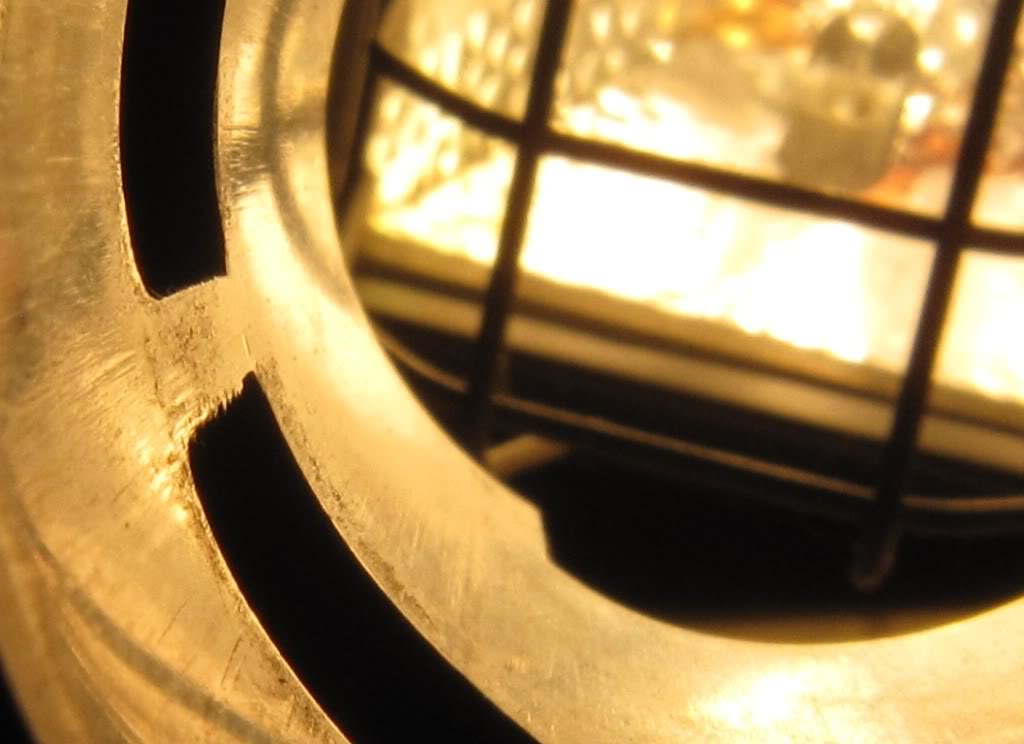

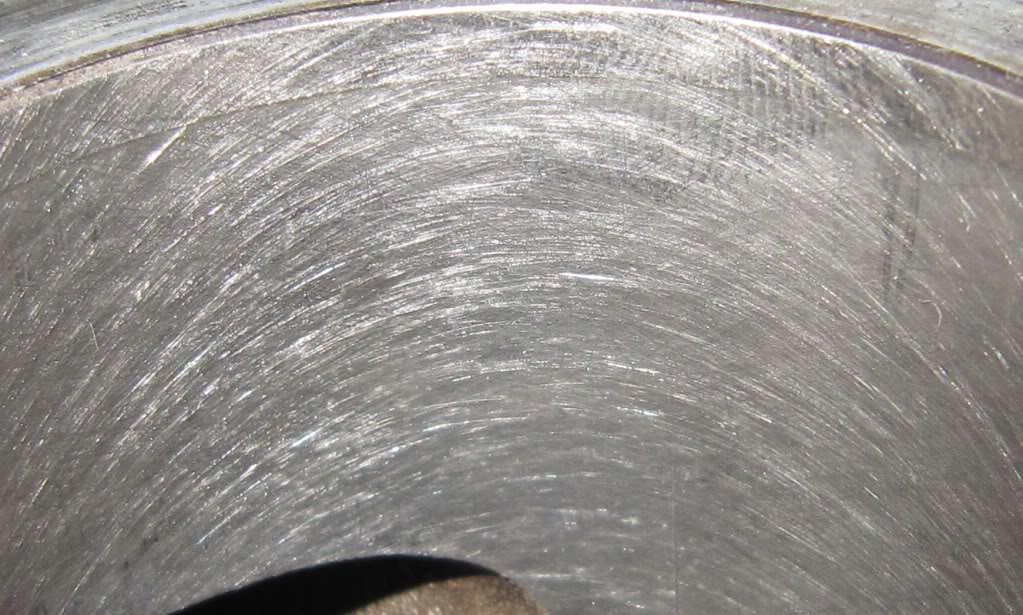

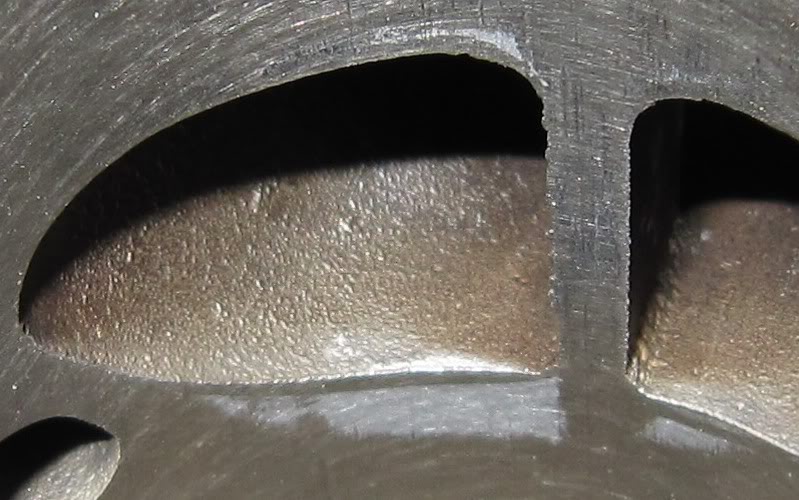

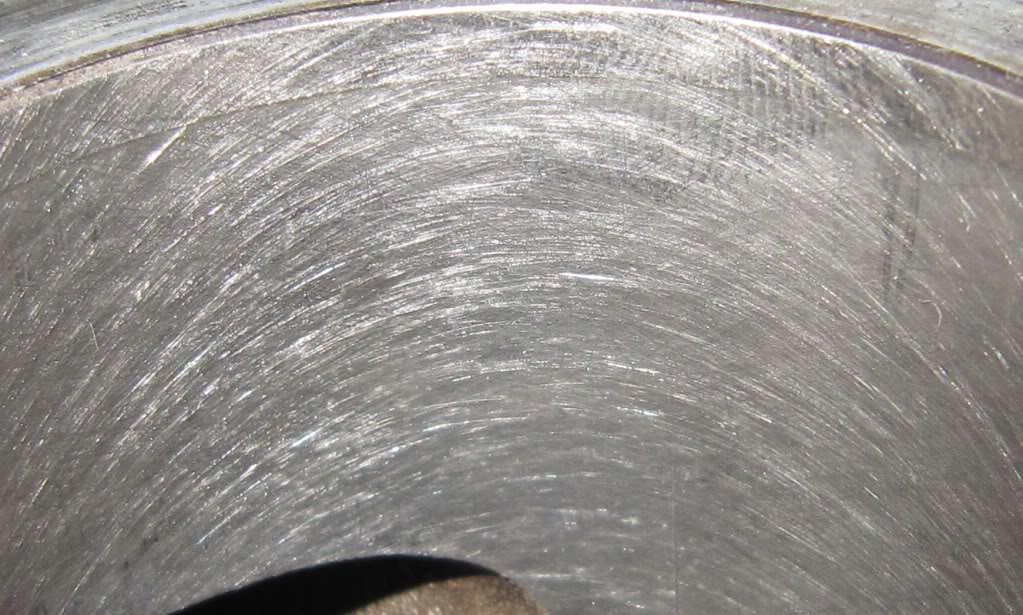

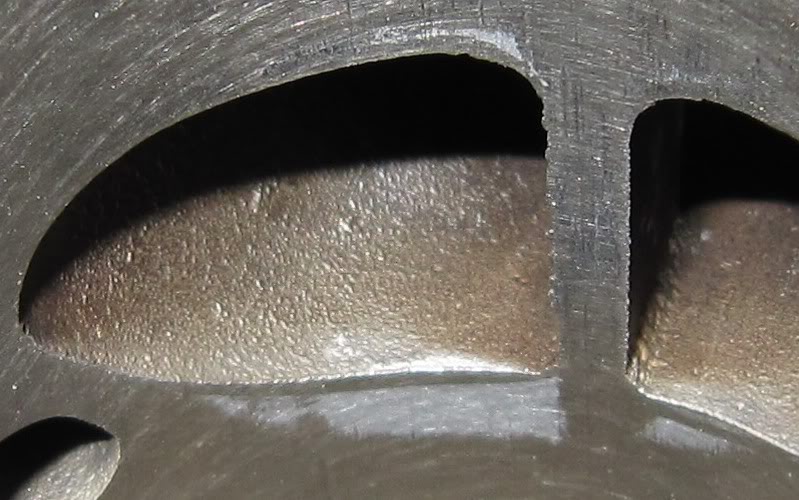

Onto the cylinder... I took like 50 pictures of the sleeve so here are the best. The main concerns seem to be on the exhaust side just like the piston. Probably most of it could be honed out but there are a few pretty deep scratches that even with a new piston and rings my buddie thinks will have some blowby since they might go deeper than the plating? Then there are the exhaust ports, one looks beat up and burnt can I just file it down and good to go?-Main goal is get it running decent for resale.

My head should be fine right?

FLUUUUCKER there's a hole in the case under the flywheel, so I called the kid I bought it from and made him give me my $50 back so I got the CR for a $100 bicycle. I'm guessing there is less oil pressure on this side compared to the clutch side (the flywheel cover is plastic) so it could have been worse? I'm going to try and patch this up because there was a patch on my lt230s like this and it's holding fine (maybe some JB weld?)

Onto the cylinder... I took like 50 pictures of the sleeve so here are the best. The main concerns seem to be on the exhaust side just like the piston. Probably most of it could be honed out but there are a few pretty deep scratches that even with a new piston and rings my buddie thinks will have some blowby since they might go deeper than the plating? Then there are the exhaust ports, one looks beat up and burnt can I just file it down and good to go?-Main goal is get it running decent for resale.

#14

Can anyone tell me why the damage would be on the exhaust side of the cylinder and piston? Is it because the exhaust side gets hotter than the other. If I move the connecting rod back and forth there is a little bit of side to side play in the bottom end where the lower shell bearing is. Hope the play is normal....

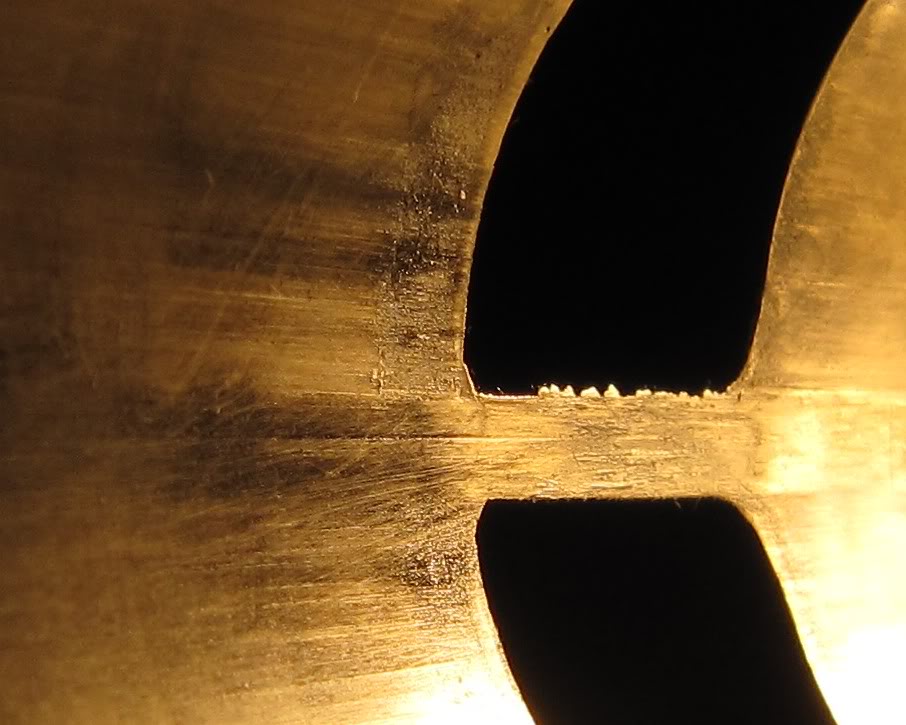

I'm guessing the jagged exhaust port is build up from the rings melting or something, they jag UP and not down in so it's a build up rather than missing chips.

#15

Rod side to side movement is normal to a degree. Just no up and down. Try pulling up on the rod with one hand and slapping down your hand with the other, if you feel it click then it needs new rod bearings. With melting the exhaust side that to me would indicate a lean condition or and exhaust flange leak. Also with a 2 stroke I read that if it's kept at a constant speed it will get too hot in one area, running at different rpm's makes the flamefront go in different areas of the piston top to even out the heat. That's why alot of people tune them to not idle.

#16

That's some good information to have about the RPM flux. I was hoping the wear on the exaust side wasen't from a bottom end problem pushing more force on one side of the cylinder than the other (like a bent connecting rod or something). My bros bike dosen't idle he bought it from a racer, so that explains that!

#17

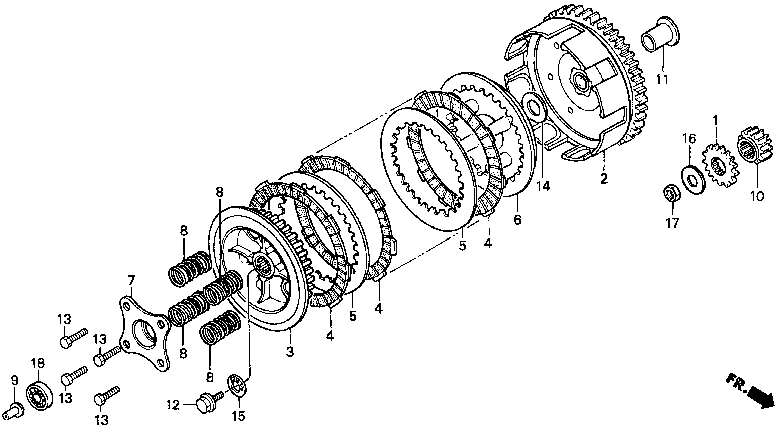

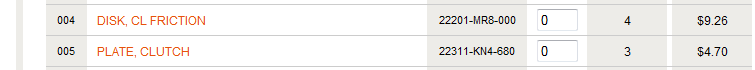

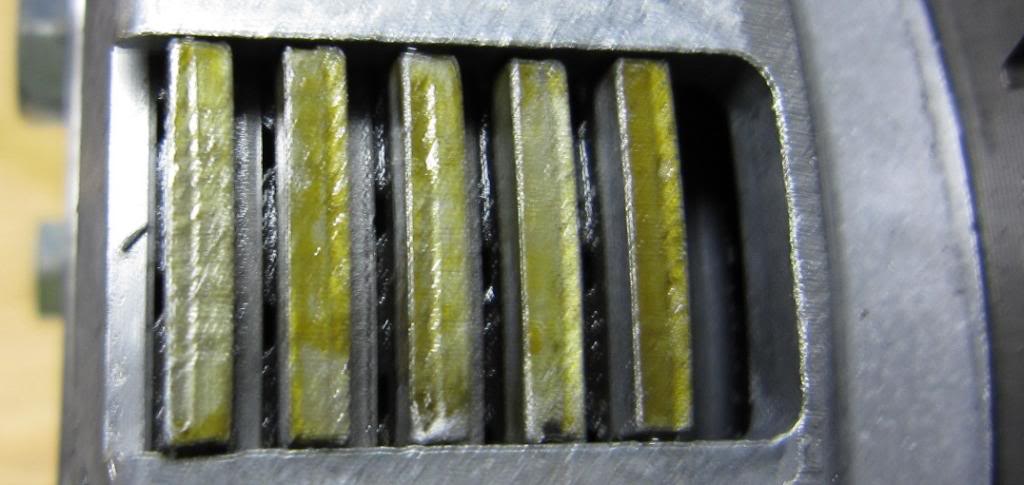

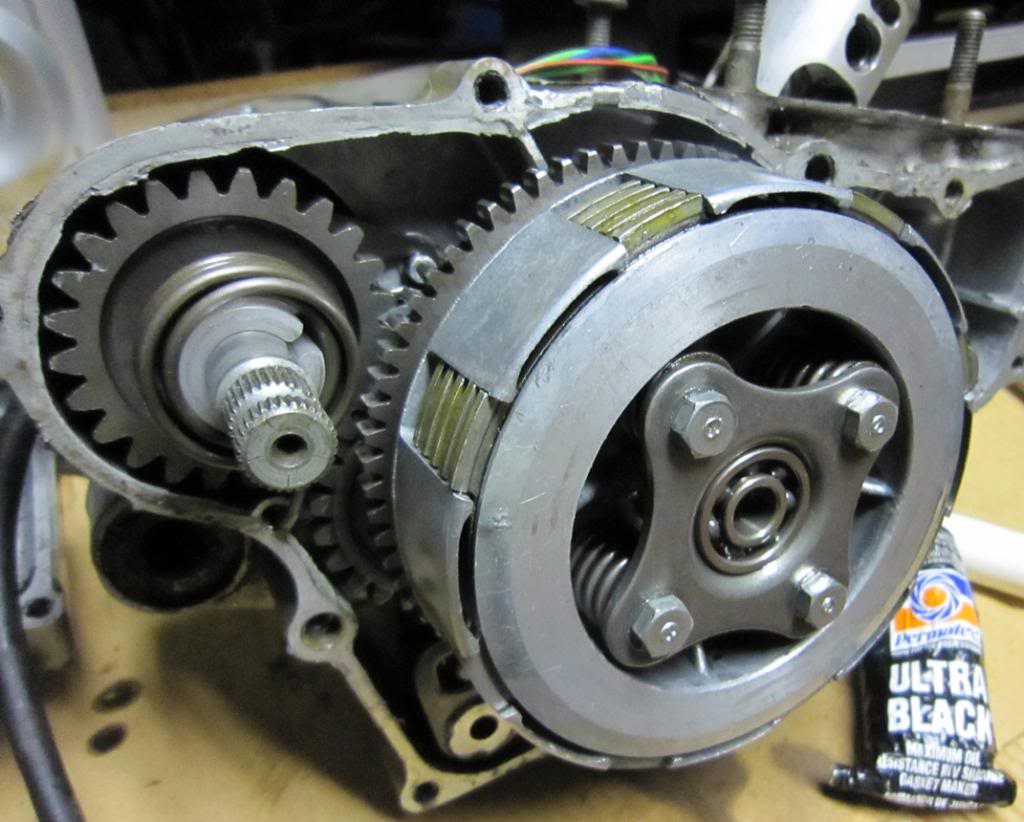

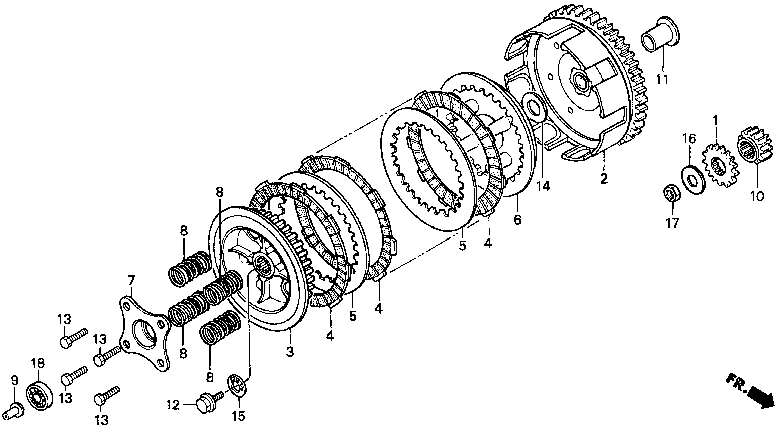

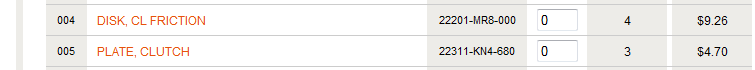

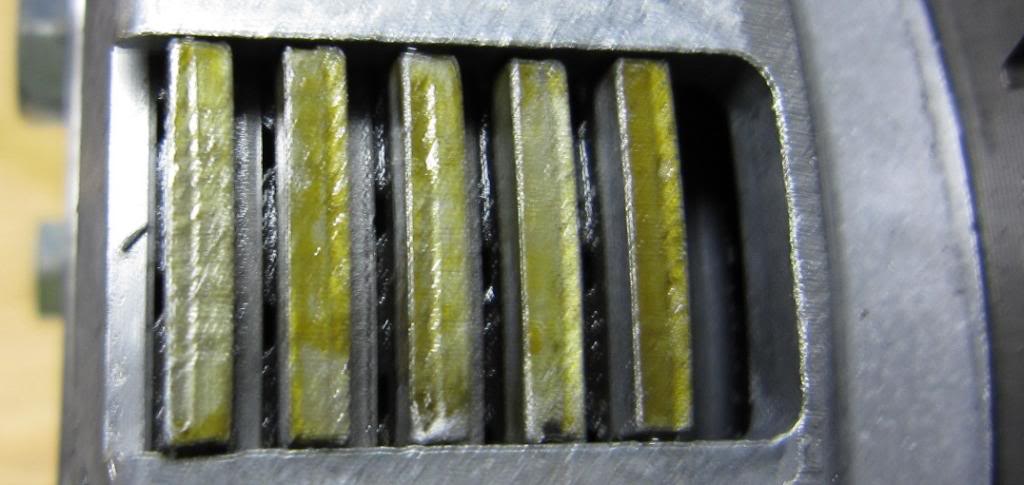

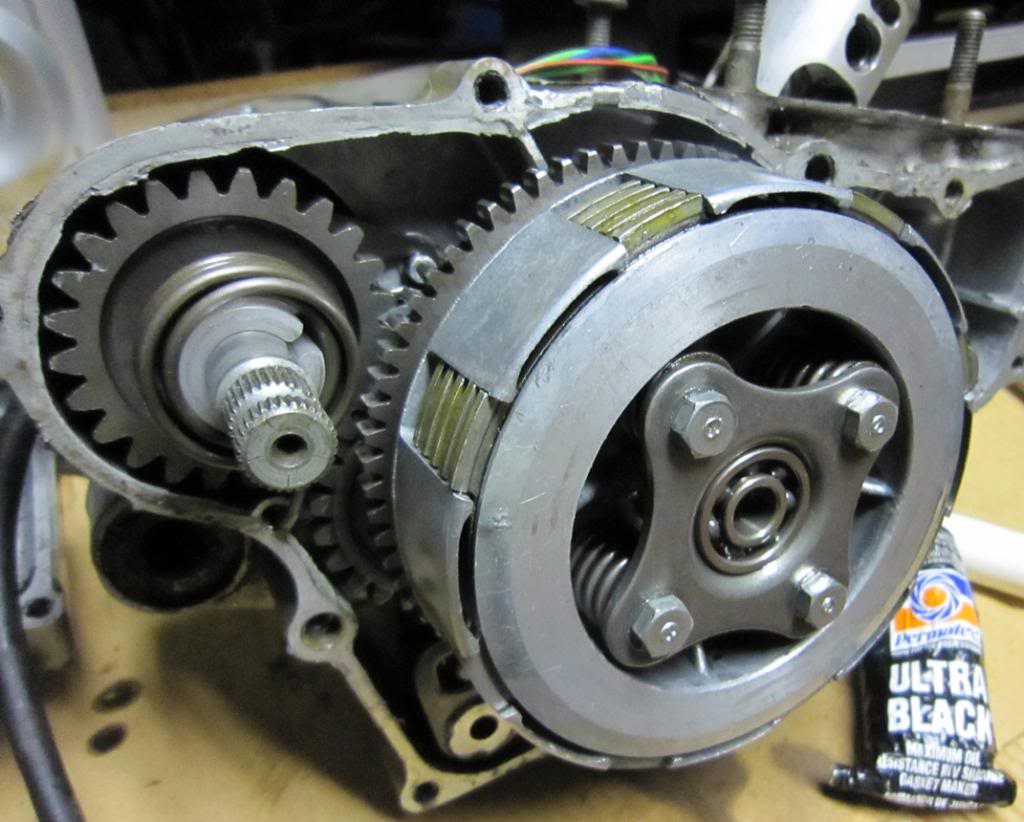

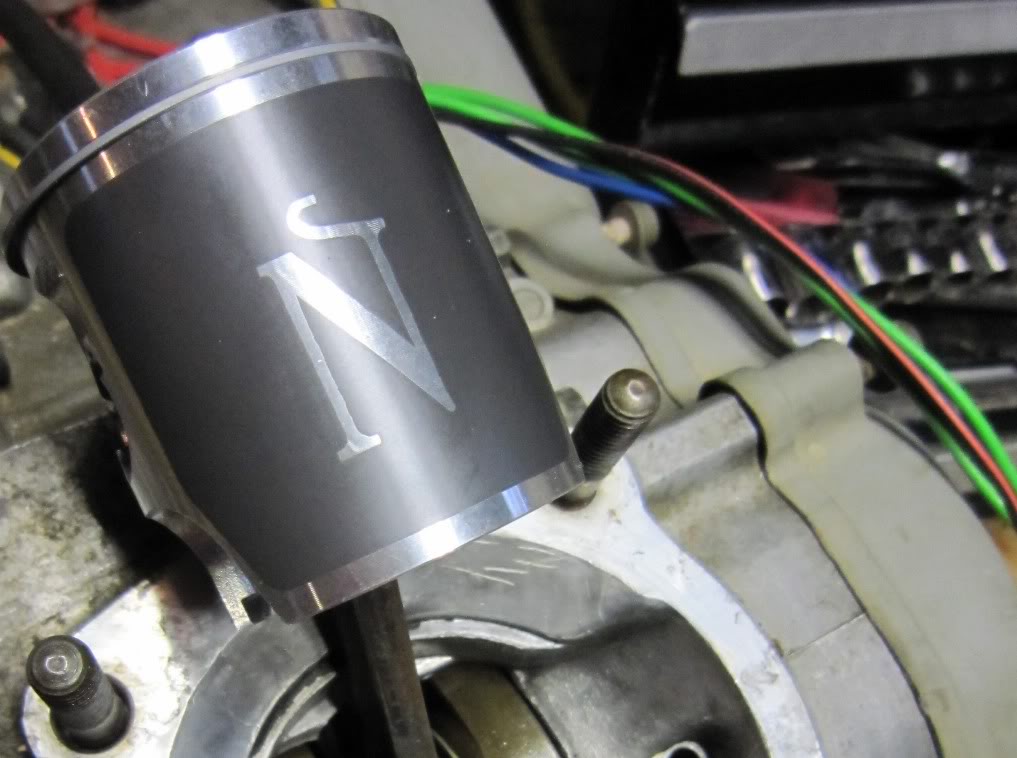

I think there is an aftermarket clutch in this bike? The assembly shows 3 plates and 4 fibers. But the clutch has 5 plates and 5-6 fibers (that look to be in good shape judging by the gaps in the squares)

No gasket on the side cover and for $100 I'm not buying one

This stuff works great though:

Dent in the clutch cover:

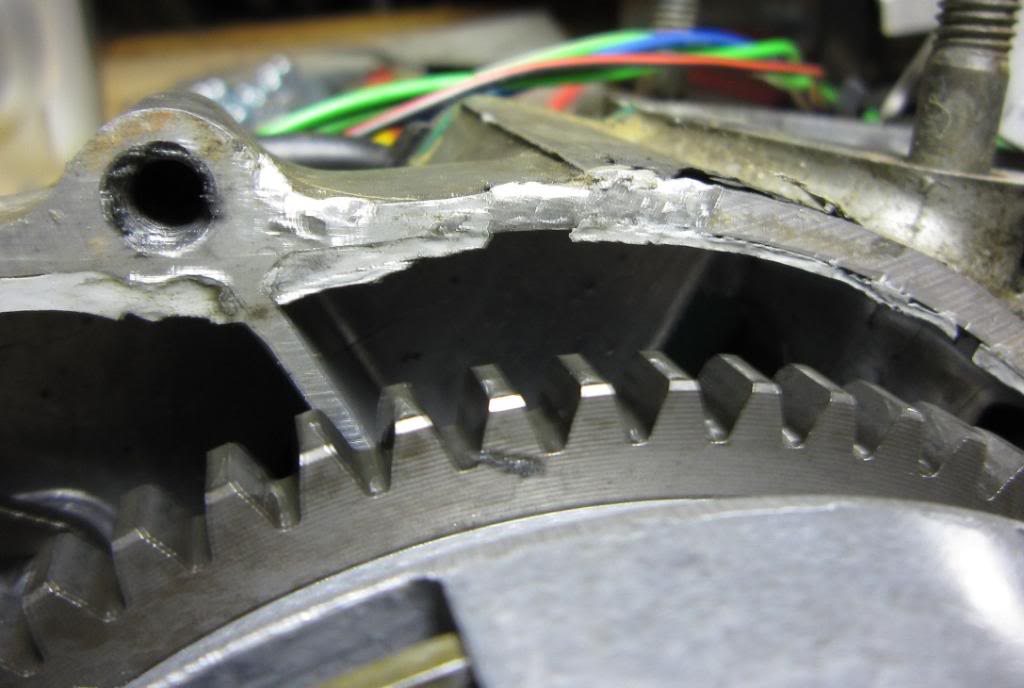

And on the inside it's cracked, I will puddy on some liquid metal/JB Weld:

I tested every single bolt for pressure and this is the only one that failed to hold, I will drill it out and healacoil it:

Some idiot must have installed the clutch wrong at one point and had to smash a screw driver between the cases to get the cover off, luckily it's on the top and some gasket maker will do the trick:

No gasket on the side cover and for $100 I'm not buying one

This stuff works great though:

Dent in the clutch cover:

And on the inside it's cracked, I will puddy on some liquid metal/JB Weld:

I tested every single bolt for pressure and this is the only one that failed to hold, I will drill it out and healacoil it:

Some idiot must have installed the clutch wrong at one point and had to smash a screw driver between the cases to get the cover off, luckily it's on the top and some gasket maker will do the trick:

#18

#19

#20

Installed the piston today:

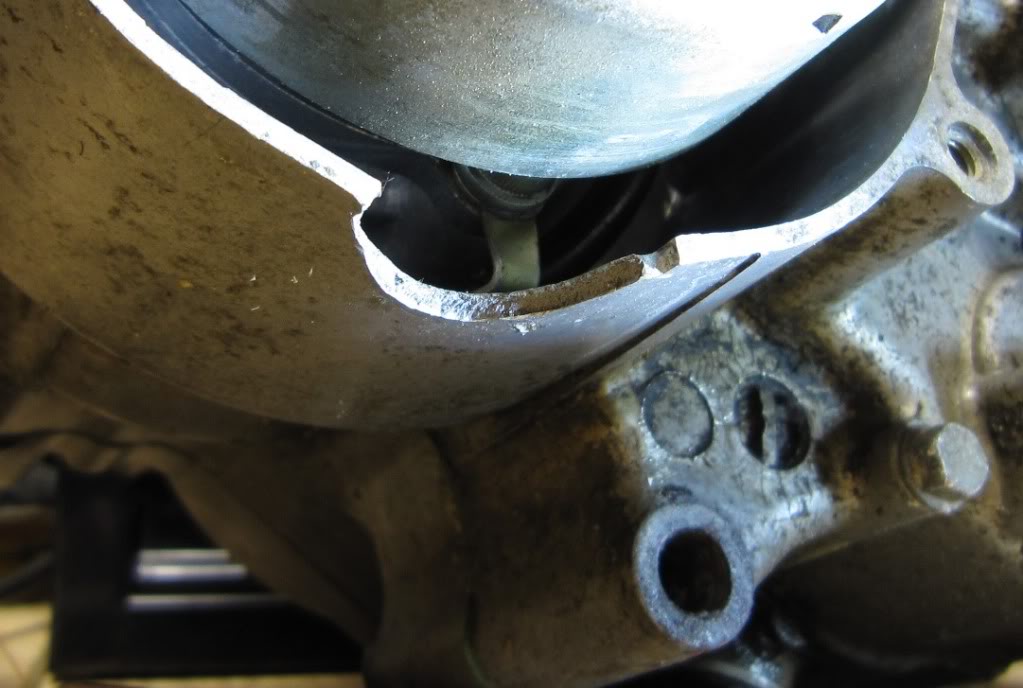

Brought the jug to my local motorcycle shop and they honed it for $15. He used a 2 stone tool, not one of those cheap up side down V shaped tools! I watched him, he poured oil of some sort on it, ran it in and out. Then instead of reversing his drill he flipped the jug and ran it through the opposite side, using a U joint fitting between the drill and hone tool. We took a look and it was not taking anything off around the exhaust ports, since there is not much to play with he took a smaller diameter ball flex hone and ran it just around that spot, which is also where you can see the chipping where the plating is gone (a few areas). The only thing I was puzzled about but did not question the guru's work is the fact he did not oil the ball hone, I assume it already had oil absorbed into the stones from previous jobs plus the oil already in the cylinder from the first hone tool? Anyway he said it's on it's absolute last leg and that he would not put it back on a bike if it were in his shop, that the edge already started and is a ticking time bomb ready to continue flaking from that area outward:

I poured some 2 stroke mix oil on my fingers and coated the cylinder walls, held the ring tight (primarily around the split area) fed it up through the cylinder skirt genitally and the jug slid down nicely:

Does anyone know how many foot lbs on the head bolts?? Also I'm going to need the stock air/fuel/idle screw settings.

^ Bicycle Trade-$100

Parts & Shipping-$105

Hone Labor-$15

___________________

Total To Date-$220

Brought the jug to my local motorcycle shop and they honed it for $15. He used a 2 stone tool, not one of those cheap up side down V shaped tools! I watched him, he poured oil of some sort on it, ran it in and out. Then instead of reversing his drill he flipped the jug and ran it through the opposite side, using a U joint fitting between the drill and hone tool. We took a look and it was not taking anything off around the exhaust ports, since there is not much to play with he took a smaller diameter ball flex hone and ran it just around that spot, which is also where you can see the chipping where the plating is gone (a few areas). The only thing I was puzzled about but did not question the guru's work is the fact he did not oil the ball hone, I assume it already had oil absorbed into the stones from previous jobs plus the oil already in the cylinder from the first hone tool? Anyway he said it's on it's absolute last leg and that he would not put it back on a bike if it were in his shop, that the edge already started and is a ticking time bomb ready to continue flaking from that area outward:

I poured some 2 stroke mix oil on my fingers and coated the cylinder walls, held the ring tight (primarily around the split area) fed it up through the cylinder skirt genitally and the jug slid down nicely:

Does anyone know how many foot lbs on the head bolts?? Also I'm going to need the stock air/fuel/idle screw settings.

^ Bicycle Trade-$100

Parts & Shipping-$105

Hone Labor-$15

___________________

Total To Date-$220