LT250R Arms

#1

Alright here's what we all know: Wide is good. Arms are expensive.

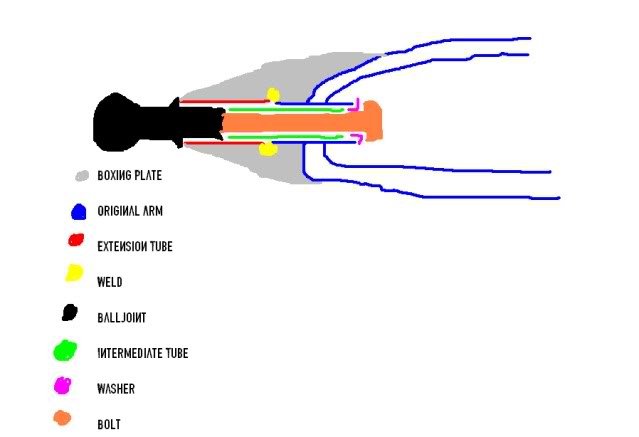

And my 86 LT250R could DEFINATLEY use some width. Ive priced out burgard, fullflight, and avenger arms. Not for me. However, i have gotten a little more comfortable with chopping and welding OEM parts (as with my LT230 arm project which is STILL A WORK IN PROGRESS, for anyone who has been following that, i havent given up!). And a little while ago i came across this in the gallery:

i tried to contact the member with no luck. so i guess ill ask my questions here since there's some really bright people on here when it comes to engineering and geometry and stuff that i dont get along with very well lol.

so, heres my questions:

will this method of widening hold up to my application? (i do mx jumps that sometimes even built 450 riders's raise an eyebrow about). I will definatley be boxing in the ends by the balljoint, like i did on my 230 arms, except they were on the opposite end. that gives lots of extra needed strength, since my butt weld skills are questionable, while in a straight line my welds seem better than OEM.

what kind of tube should i get for the extensions? is there a fancy grade to look for? it had to melt well with the OEM mild steel.

what kind of bolts should i get for the balljoints? i want the most super intense grade i can find. if there's better than 10.9, i want it lol!

thanks in advance guys.

And my 86 LT250R could DEFINATLEY use some width. Ive priced out burgard, fullflight, and avenger arms. Not for me. However, i have gotten a little more comfortable with chopping and welding OEM parts (as with my LT230 arm project which is STILL A WORK IN PROGRESS, for anyone who has been following that, i havent given up!). And a little while ago i came across this in the gallery:

i tried to contact the member with no luck. so i guess ill ask my questions here since there's some really bright people on here when it comes to engineering and geometry and stuff that i dont get along with very well lol.

so, heres my questions:

will this method of widening hold up to my application? (i do mx jumps that sometimes even built 450 riders's raise an eyebrow about). I will definatley be boxing in the ends by the balljoint, like i did on my 230 arms, except they were on the opposite end. that gives lots of extra needed strength, since my butt weld skills are questionable, while in a straight line my welds seem better than OEM.

what kind of tube should i get for the extensions? is there a fancy grade to look for? it had to melt well with the OEM mild steel.

what kind of bolts should i get for the balljoints? i want the most super intense grade i can find. if there's better than 10.9, i want it lol!

thanks in advance guys.

#3

#4

dont really know if i would suggest widening at the ball joint like that, if the front bottoms out that is a lot of stress right at those points, and with the length added at the ball joints thats just more leverage against the welds, that could be disaterous if you land and one side decides to tear away on you when you land. if its possible you would get the most strength by putting your extensions between your shocks and frame, but to keep your ground clearance you would need to find longer shocks that would fit, the chace of that happening i do not know. i dont have any advice as to what grade steel you should gt or anything like that but keep you steel around the same width.

I can give you a little advice as to welding though, i seen where you had posted about putting more wire thinking it could only add in strenght, however more is not always better you are looking for penetration when you were doing your 230 arm project it looked as though you could of slowed down how fast you were moving the tip as well as turn the heat up, and either move the tip up and down as you drag it or in small circles as you drag the tip it just depends how you would like to do it.

On the same note though your 230 arms are looking good and you need to get that project done cause i want to see the fnished project.

I can give you a little advice as to welding though, i seen where you had posted about putting more wire thinking it could only add in strenght, however more is not always better you are looking for penetration when you were doing your 230 arm project it looked as though you could of slowed down how fast you were moving the tip as well as turn the heat up, and either move the tip up and down as you drag it or in small circles as you drag the tip it just depends how you would like to do it.

On the same note though your 230 arms are looking good and you need to get that project done cause i want to see the fnished project.

#5

thanks for the welding tips, ill definatley be getting my skills tuned in before i attempt such a project.

and, i wont mess up my arms. ill order some spares to play around with. plus i'll definatley box the crap out of the end im messing with, with 1/8" plate, like i did with those 230 arms.

lastly, i'll get some friends to do the initial testing (LMFAO) and then ill probably magnaflux everything just to make sure everythings ok.

and, i wont mess up my arms. ill order some spares to play around with. plus i'll definatley box the crap out of the end im messing with, with 1/8" plate, like i did with those 230 arms.

lastly, i'll get some friends to do the initial testing (LMFAO) and then ill probably magnaflux everything just to make sure everythings ok.

#6

for an added measure of saftey, i will insert a tube with the same od and id as the small stepped part of the washer by the bolt head. it will span the distance between the back of the balljoint and the bottom of the washer. it will bridge the gap over (actually under) my weld and maybe help me out a little if something really breaks badly.

overall, my extension and the entire tube that the balljoint goes into (old and new portions) will basically be solid. the bolt, inner tube, and outer tube will all fit very snugly together.

overall, my extension and the entire tube that the balljoint goes into (old and new portions) will basically be solid. the bolt, inner tube, and outer tube will all fit very snugly together.

#7

Trending Topics

#8

that was quit the impressive drawing that you got there, looks good in theory as long as the tube in the middle is actually welded in there as part of the outside tube cause just sitting in there its not going to do anymore good to you then just dead weight, but yeah i see what you are talking about it does look about the easiest way of doing that extension

#9

dont really know if i would suggest widening at the ball joint like that, if the front bottoms out that is a lot of stress right at those points, and with the length added at the ball joints thats just more leverage against the welds, that could be disaterous if you land and one side decides to tear away on you when you land. if its possible you would get the most strength by putting your extensions between your shocks and frame, but to keep your ground clearance you would need to find longer shocks that would fit, the chace of that happening i do not know. i dont have any advice as to what grade steel you should gt or anything like that but keep you steel around the same width.

I can give you a little advice as to welding though, i seen where you had posted about putting more wire thinking it could only add in strenght, however more is not always better you are looking for penetration when you were doing your 230 arm project it looked as though you could of slowed down how fast you were moving the tip as well as turn the heat up, and either move the tip up and down as you drag it or in small circles as you drag the tip it just depends how you would like to do it.

On the same note though your 230 arms are looking good and you need to get that project done cause i want to see the fnished project.

I can give you a little advice as to welding though, i seen where you had posted about putting more wire thinking it could only add in strenght, however more is not always better you are looking for penetration when you were doing your 230 arm project it looked as though you could of slowed down how fast you were moving the tip as well as turn the heat up, and either move the tip up and down as you drag it or in small circles as you drag the tip it just depends how you would like to do it.

On the same note though your 230 arms are looking good and you need to get that project done cause i want to see the fnished project.

also V out both ends of your pipe it makes it alot better for penatration. but dont go to slow with the welds because you can blow through it but number one thing is get confortable into do it practice a bit first on some scrap and then go to it. keep good heat and good penatration the you shouldnt have anything to worry about. with deeper penetration you are basically welding on both sides of the pipe with as then as the steel is.

#10

Thread

Thread Starter

Forum

Replies

Last Post

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)