ATV Tech: Secrets Of The Valve Train

The science behind the process.

When it comes to a four-stroke engine, there is a very simple process taking place every single time your piston rockets up and down its cylinder bore – your intake and exhaust valves open and close once per every two crank revolutions. That means your piston goes up twice and down twice per every cycle – four strokes.

We know this is happening – but do we ever stop to really think about what makes this process take place? How are valves opening and closing at the exact correct interval to allow fuel and air to enter the cylinder and then closing so that another set of valves can open to allow for the expulsion of waste gas?

The answer of course is the camshaft. The camshaft makes use of lobes (elongated circles) that, when rotated, become little pushers. They push open the valve and a spring then closes it when the lobe continues on past the valve stem until its next trip around. Simple right? Not so fast.

We’d have major problems if the cam lobe was smacking directly against the valve dozens of times a second. Unless they were made of something as hard as diamond, they’d be blown apart pretty quickly.

Some sort of buffer is necessary to take the brunt of those lobes swinging around while still making direct contact with the valve. Enter the tappet.

For years the “bucket and shim” tappet has been the design of choice for this application. So named because it looks like, well, a little bucket, it would take the direct contact of the spinning cam lobes and transfer it downward onto the actual valve. As for the shim portion of the name – this is exactly what it sounds like – adjusting the space between the valve and bucket was simply a matter of stacking up or removing shims.

This is still the prevailing methodology implemented in our ATVs and Side-By-Sides today. It is reliable, easy to adjust and time tested. The only trouble with it is that it is a bulky system, adding to size of the cylinder, and contains multiple moving parts.

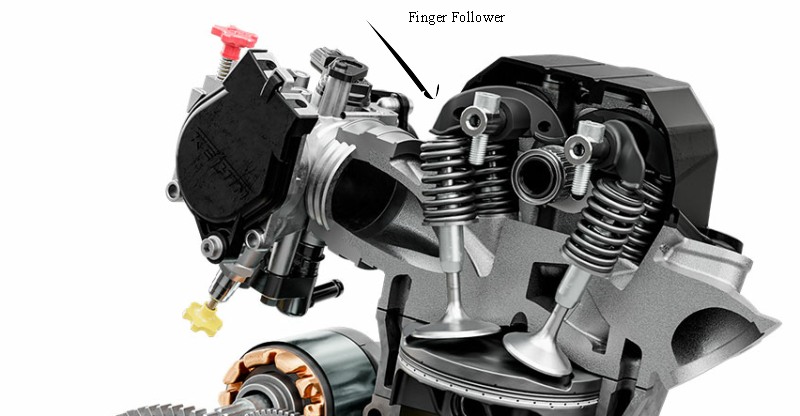

As such, there is another method gaining traction that you are more likely to find on performance-oriented machines: Finger followers.

These are little forged rocker arms that pivot directly off the cam lobes directly above the valve springs that push open the valve with fewer parts and complexity than the bucket and shim system.

Its origins can be traced back to F1, where saving ounces by being able to cast smaller cylinders is paramount. Additionally, they proved very successful at maintaining higher RPM loads consistently thanks to there being fewer parts in motion to fail.

With finger followers, specific shapes can be achieved in either the forging or machining that allow for shorter duration, but higher valve lift – all while reducing engine weight in the process.

You may remember hearing about this configuration back in 2009 when KTM’s short-lived performance ATV line made use of dual overhead camshafts and DLC-coated finger followers to drive four titanium valves.

For more information on valve adjustment, we covered that here.