No spark coolster 110cc 1 of many thanks for looking

#11

Join Date: Dec 2008

Location: Tracy, California, USA

Posts: 3,260

Likes: 0

Received 13 Likes

on

13 Posts

Performed all tests again and all results were the same. I also had the lights off in the garage when checking with the led's, still didn't see any lights.

Took the led tester to work and hooked it up to a regulated power supply. The minimum voltage it took to light them was 2.13 volts guess that explains not being able to see them.

Took the led tester to work and hooked it up to a regulated power supply. The minimum voltage it took to light them was 2.13 volts guess that explains not being able to see them.

. You're confusing the trigger voltage (measured with a meter) versus the peak trigger signal which is a brief pulse that happens infrequently. These cannot be casually compared.

. You're confusing the trigger voltage (measured with a meter) versus the peak trigger signal which is a brief pulse that happens infrequently. These cannot be casually compared.Your description of the 2.13 volt threshold for lighting the LED's is 100% correct, and 100% *required* for testing the trigger signal. The forward barrier voltage of an LED gallium arsenide semiconductor junction is around 2 volts (a little less for red LEDs and a little more for green or blue). In the forward direction no current flows until this barrier voltage is overcome, and that is *exactly* what we are trying to measure.

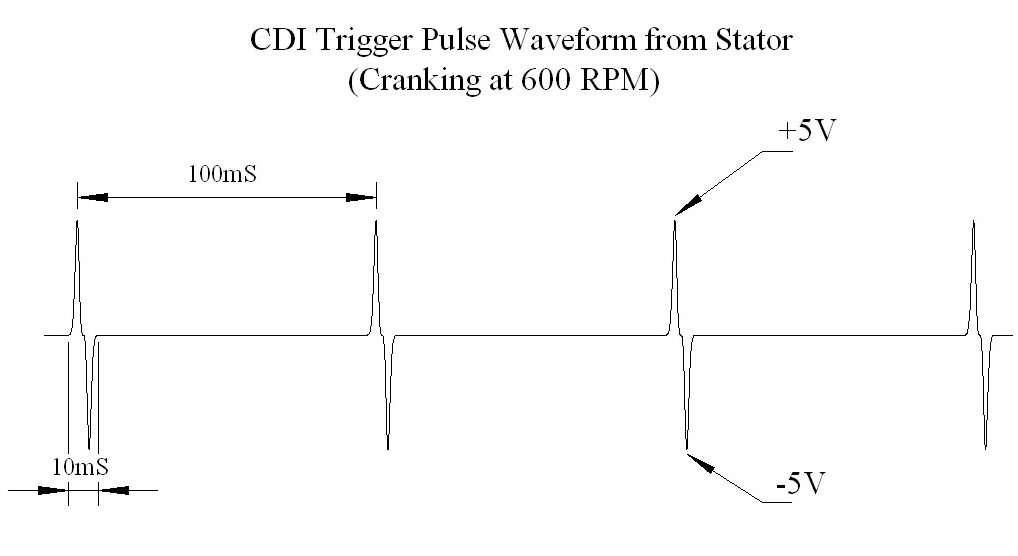

Let's back up a bit, and look at the typical trigger voltage signal at cranking speeds:

In the above graph is displayed what you would see with an oscilloscope. An oscilloscope is nothing more than a fancy volt meter that measures voltage that are moving quickly over time. It grabs them and plots them out. Voltage is on the vertical axis, and time is on the hoizontal axis.

Note how the voltage briefly exceeds 2.13 volts when the trigger signal arrives at the CDI. There is a positive pulse that exceede the barrier voltage, and a negative pulse too. On both of these excusions current should flow in both directions, lighting up one LED or the other. Because the duty cycle is low (most of the time the voltage is too low for current to flow), so the LED light intensity will be dim. But you should be able to see it. Note though, that the time that the voltage spends above 2.13 volts for each LED is about 3 or 4 percent of the total time. So your really do need to expect a "dim" light, though you should easily be able to see this in (say) a garage with hands cupped over the LEDs.

Now lets look at what a typical voltmeter does with this complicated trigger waveform:

Most meters are designed with the assumption that they will be measuring sine wave (i.e. household power voltages). When subjected to weird shaped waveform like the trigger signal above many perform poorly. Most meter will *average* the AC voltage over time (like 0.5 seconds). So all those 5 volt peak signals get averaged together with the rest of the waveform which is sitting at zero volts. This is why a signal with a 5 volt peak amplitude measures in at 5% of that (like 0.2 volts). Worse, different meters perform differently with non standard waveforms, so there is another confounding variable. And many meters only measure AC voltages at 200 volts full scale, so now we add in another minimum measurement resolution error.

It would be great if everyone had an oscilloscope. But this is impractical. Meters are often the best tool we have. So we do the best we can with what we have. Then we analyze the results taking into consideration the limitations of the equipment at hand, and make the best imformed choice based on limited info.

I hope this makes at least a little sense...

.

....So are you leaning towards the coil being faulty?

Our Part dealer for these chineese ATV's here in Chicago wants $45 for a new coil! Seems like a rip-off

Internet you can find them for $18 I guess, both have no gaurantee. Any thoughts, do you think they're the same?

Can the coil be tested further?

Thanks for the help.

Our Part dealer for these chineese ATV's here in Chicago wants $45 for a new coil! Seems like a rip-off

Internet you can find them for $18 I guess, both have no gaurantee. Any thoughts, do you think they're the same?

Can the coil be tested further?

Thanks for the help.

Changing the coil is a bit preamature yet, but I would buy coils off the internet before paying $45 locally. Do google searches on whatever vendor you choose and look at their reputation. The coils for four stroke generic chinese quads are the same electrically if they use the 4 pin, 5 pin, or six pin generic CDI (which most do). You need to make sure it will bolt up mechanically.

I would not try to substitute a generic 2 cycle coil.

#12

Okay that makes sense, what your saying is that the meter doesn't capture the full voltage, in my case .221VAC in my case, but it should be enough to lite the LED's.

I tried it again with the lights off and I see nothing at all that resembles the LED's wanting to light.

I still see the voltage at the CDI plug which is unplugged

The LED's were plugged in without the CDI being attached. Is this correct

Your saying my other voltages dropping off from 49.7VAC down to 26.3 VAC indicates the CDI is being triggered, this doesn't make sense that my LED's aren't lighting

this ATV had a remote kill box on it, I removed it by unplugging it at the connector which has 1 green 1 black and 1 black/white stripe wire in it. This should be all I have to do to disable it RIGHT?

All the kill box did was let the ATV run or not run, which means to have spark or not to have spark! Correct

With it disconnected I see the voltage but the LED's don't light ( maybe my tester is just that good and that's all the voltage there is .221 VAC

I removed the stator and visually it looks fine, nothing stuck to the trigger or anywhere else for that matter. All wires seem good, and it tested fine by the readings, right

I still get the readings I have been.

This all started when my son tried hot wiring the key switch and not knowing which wires out of the four to touch to get it to crank.

I tried it again with the lights off and I see nothing at all that resembles the LED's wanting to light.

I still see the voltage at the CDI plug which is unplugged

The LED's were plugged in without the CDI being attached. Is this correct

Your saying my other voltages dropping off from 49.7VAC down to 26.3 VAC indicates the CDI is being triggered, this doesn't make sense that my LED's aren't lighting

this ATV had a remote kill box on it, I removed it by unplugging it at the connector which has 1 green 1 black and 1 black/white stripe wire in it. This should be all I have to do to disable it RIGHT?

All the kill box did was let the ATV run or not run, which means to have spark or not to have spark! Correct

With it disconnected I see the voltage but the LED's don't light ( maybe my tester is just that good and that's all the voltage there is .221 VAC

I removed the stator and visually it looks fine, nothing stuck to the trigger or anywhere else for that matter. All wires seem good, and it tested fine by the readings, right

I still get the readings I have been.

This all started when my son tried hot wiring the key switch and not knowing which wires out of the four to touch to get it to crank.

#13

Join Date: Dec 2008

Location: Tracy, California, USA

Posts: 3,260

Likes: 0

Received 13 Likes

on

13 Posts

My comments in blue:

Okay that makes sense, what your saying is that the meter doesn't capture the full voltage, in my case .221VAC in my case, but it should be enough to lite the LED's. [Yes, the meter does some sort of averaging of the voltage, so it will read way low of the peak trigger voltage. But it is the peak trigger voltage that is important. The peak part of the waveform is what triggers the CDI. Actually it is a little more complex than that]. On most CDIs the first positive peak "arms" the CDI, and the second negative peak *fires* the CDI. This "arming" then "firing" sequence prevents false triggers from happening at really inopertune times such as at the beginning of the compression stroke.

I tried it again with the lights off and I see nothing at all that resembles the LED's wanting to light. [I think this really indicates a low trigger signal.]

I still see the voltage at the CDI plug which is unplugged

The LED's were plugged in without the CDI being attached. Is this correct [Yes.]

Your saying my other voltages dropping off from 49.7VAC down to 26.3 VAC indicates the CDI is being triggered, this doesn't make sense that my LED's aren't lighting [I have to back away from this statement. Here's the whole story: There was a post a few weeks back about someone with an AC powered CDI with spark problems. He reported that the AC ignition power voltage was the same when the CDI was hooked up as when it was disconnected. This shouldn't be, because the CDI during its normal operation jacks the AC ignition power voltage around a lot (the stator output is inherently current limited so that is easy to do). His problem was that the CDI was not getting triggered, and when he fixed that problem the AC ignition power was now different when the CDI was hooked up versus when it wasn't. I latched onto this as a possible good troubleshooting technique - i.e. measure the two voltages, and that would indicate whether the CDI was getting triggered or not. It was a good idea, but it didn't pan out. Measuring my own quad (and verifying what I found by looking at CDI internal circuit diagrams) I found that this doesn't work well as a diagnostic procedure. Whether or not your CDI is getting triggered, the AC ignition power voltage will be substantially reduced when you hook up the CDI. If the CDI *is* getting triggered the voltage will drop more, but not by enough to stick out enough above all the other confounding variables between different quad designs. I was hopeful, but my measurements this weekend disspelled any easy solution using this technique. Sorry about using you for a guinea pig to go down what turns out to be a blind alley.]

this ATV had a remote kill box on it, I removed it by unplugging it at the connector which has 1 green 1 black and 1 black/white stripe wire in it. This should be all I have to do to disable it RIGHT? [Correct. The black white wire is shorted to ground (green wire) to kill spark. The two wires are disconnected to enable spark. When you unplug that connector the remote kill module can not short those two wires anymore - so spark is enabled (unless another kill switch on this wiring bus is shorting this wire to ground).]

All the kill box did was let the ATV run or not run, which means to have spark or not to have spark! Correct [Yes.]

With it disconnected I see the voltage but the LED's don't light ( maybe my tester is just that good and that's all the voltage there is .221 VAC

I removed the stator and visually it looks fine, nothing stuck to the trigger or anywhere else for that matter. All wires seem good, and it tested fine by the readings, right

I still get the readings I have been. [Repeatability is good]

This all started when my son tried hot wiring the key switch and not knowing which wires out of the four to touch to get it to crank.

[The four wires are:

[The four wires are:

1) Fused power

2) Switched fused power

3) Ground

4) Kill switch.

When the ignition switch is on, 1) and 2) are shorted, while 3) and 4) are off.

When the ignition switch is off, 1) and 2) are off, while 3) and 4) are shorted.

If you have fuse installed in a no hacked wiring harness you cannot harm anything by shorting any combination of wires in the ignition switch other than blowing a fuse]

I tried it again with the lights off and I see nothing at all that resembles the LED's wanting to light. [I think this really indicates a low trigger signal.]

I still see the voltage at the CDI plug which is unplugged

The LED's were plugged in without the CDI being attached. Is this correct [Yes.]

Your saying my other voltages dropping off from 49.7VAC down to 26.3 VAC indicates the CDI is being triggered, this doesn't make sense that my LED's aren't lighting [I have to back away from this statement. Here's the whole story: There was a post a few weeks back about someone with an AC powered CDI with spark problems. He reported that the AC ignition power voltage was the same when the CDI was hooked up as when it was disconnected. This shouldn't be, because the CDI during its normal operation jacks the AC ignition power voltage around a lot (the stator output is inherently current limited so that is easy to do). His problem was that the CDI was not getting triggered, and when he fixed that problem the AC ignition power was now different when the CDI was hooked up versus when it wasn't. I latched onto this as a possible good troubleshooting technique - i.e. measure the two voltages, and that would indicate whether the CDI was getting triggered or not. It was a good idea, but it didn't pan out. Measuring my own quad (and verifying what I found by looking at CDI internal circuit diagrams) I found that this doesn't work well as a diagnostic procedure. Whether or not your CDI is getting triggered, the AC ignition power voltage will be substantially reduced when you hook up the CDI. If the CDI *is* getting triggered the voltage will drop more, but not by enough to stick out enough above all the other confounding variables between different quad designs. I was hopeful, but my measurements this weekend disspelled any easy solution using this technique. Sorry about using you for a guinea pig to go down what turns out to be a blind alley.]

this ATV had a remote kill box on it, I removed it by unplugging it at the connector which has 1 green 1 black and 1 black/white stripe wire in it. This should be all I have to do to disable it RIGHT? [Correct. The black white wire is shorted to ground (green wire) to kill spark. The two wires are disconnected to enable spark. When you unplug that connector the remote kill module can not short those two wires anymore - so spark is enabled (unless another kill switch on this wiring bus is shorting this wire to ground).]

All the kill box did was let the ATV run or not run, which means to have spark or not to have spark! Correct [Yes.]

With it disconnected I see the voltage but the LED's don't light ( maybe my tester is just that good and that's all the voltage there is .221 VAC

I removed the stator and visually it looks fine, nothing stuck to the trigger or anywhere else for that matter. All wires seem good, and it tested fine by the readings, right

I still get the readings I have been. [Repeatability is good]

This all started when my son tried hot wiring the key switch and not knowing which wires out of the four to touch to get it to crank.

[The four wires are:

[The four wires are:1) Fused power

2) Switched fused power

3) Ground

4) Kill switch.

When the ignition switch is on, 1) and 2) are shorted, while 3) and 4) are off.

When the ignition switch is off, 1) and 2) are off, while 3) and 4) are shorted.

If you have fuse installed in a no hacked wiring harness you cannot harm anything by shorting any combination of wires in the ignition switch other than blowing a fuse]

#14

Well at this point I'm lookin for an educated guess. I have removed the stator and bench tested trigger an charge coil an got same results that I have been getting 136 ohms for trigger to ground and 318 for the charge coil

I reinstalled stator in case and mounted it back on engine connected LEDS to stator connector and cranked engine still no light and attached meter probes and still have .221 VAC at trigger coil wires.

There doesn't seem to be any adjustment for the trigger coil that ive read should be about .025 either.

Would seem to me it's not a harness problem and is pointing to stator.

What do you think.

I reinstalled stator in case and mounted it back on engine connected LEDS to stator connector and cranked engine still no light and attached meter probes and still have .221 VAC at trigger coil wires.

There doesn't seem to be any adjustment for the trigger coil that ive read should be about .025 either.

Would seem to me it's not a harness problem and is pointing to stator.

What do you think.

#15

Join Date: Dec 2008

Location: Tracy, California, USA

Posts: 3,260

Likes: 0

Received 13 Likes

on

13 Posts

I've actually been thinking about this problem a lot  .

.

The thing I'm wondering is this:

Your LEDs in the trigger fixture don't light up, so that says the peak trigger voltage must be less than 2 volts. I've never seen a quad where the LED fixture doesn't work (unless there is a trigger problem of course). That points toward a trigger problem.

But you also do measure a trigger voltage on your meter. So something is coming out. The data in this paragraph conflicts with the last paragraph. So let's imagine for the moment that there is a trigger voltage there, and it is 1.8 volts peak (instead of 5 volts peak) at cranking speeds. Will that be enough to trigger the CDI? I don't know. You don't have any output from the CDI to the ignition coil. That too suggests that there isn't any trigger pulse, or that the CDI is bad.

If only there was an oscilloscope available! .

.

A while back there was another post from someone who used a meter with an old fashioned moving needle type display (a D'Arsonval style meter). Even though the average voltage was really low when measuring the trigger signal he could see the meter needle "ticking" and 10 times per second, which indicated that trigger pulses where happening at cranking speeds. If you have one of those relics you can try that to establish another data point.

We're down to playing the odds las vegas style. If this were my problem and I didn't have a 'scope, then I would try changing the stator first, then the CDI, then the ignition coil. Because of the difficulty in changing the stator compared to just plugging in a new CDI, I could be swayed into changing the CDI, then the stator. Fortunately the parts are easy to find and cheap as well.

When I started doing this a couple years ago I would come home from work and knock out post after post of *easy* problems. Lately they are becoming a lot more difficult . I suspect that the search engine results are now solving the vast majority of the easy ones...

. I suspect that the search engine results are now solving the vast majority of the easy ones...  .

.

.

. The thing I'm wondering is this:

Your LEDs in the trigger fixture don't light up, so that says the peak trigger voltage must be less than 2 volts. I've never seen a quad where the LED fixture doesn't work (unless there is a trigger problem of course). That points toward a trigger problem.

But you also do measure a trigger voltage on your meter. So something is coming out. The data in this paragraph conflicts with the last paragraph. So let's imagine for the moment that there is a trigger voltage there, and it is 1.8 volts peak (instead of 5 volts peak) at cranking speeds. Will that be enough to trigger the CDI? I don't know. You don't have any output from the CDI to the ignition coil. That too suggests that there isn't any trigger pulse, or that the CDI is bad.

If only there was an oscilloscope available!

.

.A while back there was another post from someone who used a meter with an old fashioned moving needle type display (a D'Arsonval style meter). Even though the average voltage was really low when measuring the trigger signal he could see the meter needle "ticking" and 10 times per second, which indicated that trigger pulses where happening at cranking speeds. If you have one of those relics you can try that to establish another data point.

We're down to playing the odds las vegas style. If this were my problem and I didn't have a 'scope, then I would try changing the stator first, then the CDI, then the ignition coil. Because of the difficulty in changing the stator compared to just plugging in a new CDI, I could be swayed into changing the CDI, then the stator. Fortunately the parts are easy to find and cheap as well.

When I started doing this a couple years ago I would come home from work and knock out post after post of *easy* problems. Lately they are becoming a lot more difficult

. I suspect that the search engine results are now solving the vast majority of the easy ones...

. I suspect that the search engine results are now solving the vast majority of the easy ones...  .

.

#16

#17

Join Date: Dec 2008

Location: Tracy, California, USA

Posts: 3,260

Likes: 0

Received 13 Likes

on

13 Posts

I like the idea of passing a magnet or piece of steel across the pickup coil. I hadn't thought of doing that. Its a great idea. The "ohms fluctuation" is indicating that the pick up coil is generating a voltage which is being added to the voltage the ohmmeter is producing. It says your pickup coil is producing something. We seem to be in a gray area here...

I've thought about a stand alone CDI test routine, but haven't come up with any easy way to do this. To test the CDI you'll need power (whether it be AC or DC), a trigger signal, and the ignition coil hooked to a spark plug. The main difficulty is the the trigger signal. It has to pulse positive *and* negative to produce spark. The first pulse "arms" the CDI, and the second pulse "fires" the CDI. They happen close together. This negates using a simple push button switch in place of the trigger signal. Yeah, one could make a circuit that produces a positive pulse when pushing the switch, and a negative one when the switch is released, but this has more than three parts in it. Plus the switch release would have to happen very quickly after pushing it in else the CDI times out and disarms itself before the switch is released. It's too complicated for general use.

I've thought about a stand alone CDI test routine, but haven't come up with any easy way to do this. To test the CDI you'll need power (whether it be AC or DC), a trigger signal, and the ignition coil hooked to a spark plug. The main difficulty is the the trigger signal. It has to pulse positive *and* negative to produce spark. The first pulse "arms" the CDI, and the second pulse "fires" the CDI. They happen close together. This negates using a simple push button switch in place of the trigger signal. Yeah, one could make a circuit that produces a positive pulse when pushing the switch, and a negative one when the switch is released, but this has more than three parts in it. Plus the switch release would have to happen very quickly after pushing it in else the CDI times out and disarms itself before the switch is released. It's too complicated for general use.

#18

Okay so I removed the side cover and looked at the pick up coil in relation to the acces holes for timing, no way to measure the air gap for the pickup.

Lined up the high spot with the pick up and put cover on top alignment pin of case and could feel the gap. removed cover and loosened pickup screws and moved it in slightly. Reassembled and hooked up the LED's and still no lights while cranking. Repeated above steps two more times and now I have the LED's lighting.

Plugged the CDI back in and cranked with meter on 20 VAC scale. Meter read 0.00 with ignition on, cranking meter was reading 0.03, 0.05, 0.04, 0.03 stop cranking and meter returned to 0.00 VAC

Didn't see spark at plug.

Installed high performance CDI and checked AC voltage, meter read 0.00 ignition on, cranking it read 0.12, 0.14, 0.10 stop cranking meter returned to 0.00 VAC

Checked plug and seen what seemed like weak spark.

Installed plug and tried to start, didn't really seem to encouraging, went and bought a NGK 7HSA plug and checked spark, seemed weaker than the original that I started with.

I sprayed a little starting fluid at the air cleaner and it did fire a little but didn't stay running. Tightened all the connectors that hook up to the CDI, that didn't seem to help.

Rechecked plug for spark and don't see any, removed CDI and installed LED's and they are still lighting.

Not sure what I should try next?

All readings are same 320 ohms AC ign power pin to ground.137 ohms timing trigger to ground, 41.3 VAC ignition pin while cranking, .211VAC trigger while cranking.

Spark, air, gas, should run! To me it seems like a weak spark, could it be weak CDI or weak pick up coil

Battery is charged and starter cranks fast. Any ideas, thanks

Lined up the high spot with the pick up and put cover on top alignment pin of case and could feel the gap. removed cover and loosened pickup screws and moved it in slightly. Reassembled and hooked up the LED's and still no lights while cranking. Repeated above steps two more times and now I have the LED's lighting.

Plugged the CDI back in and cranked with meter on 20 VAC scale. Meter read 0.00 with ignition on, cranking meter was reading 0.03, 0.05, 0.04, 0.03 stop cranking and meter returned to 0.00 VAC

Didn't see spark at plug.

Installed high performance CDI and checked AC voltage, meter read 0.00 ignition on, cranking it read 0.12, 0.14, 0.10 stop cranking meter returned to 0.00 VAC

Checked plug and seen what seemed like weak spark.

Installed plug and tried to start, didn't really seem to encouraging, went and bought a NGK 7HSA plug and checked spark, seemed weaker than the original that I started with.

I sprayed a little starting fluid at the air cleaner and it did fire a little but didn't stay running. Tightened all the connectors that hook up to the CDI, that didn't seem to help.

Rechecked plug for spark and don't see any, removed CDI and installed LED's and they are still lighting.

Not sure what I should try next?

All readings are same 320 ohms AC ign power pin to ground.137 ohms timing trigger to ground, 41.3 VAC ignition pin while cranking, .211VAC trigger while cranking.

Spark, air, gas, should run! To me it seems like a weak spark, could it be weak CDI or weak pick up coil

Battery is charged and starter cranks fast. Any ideas, thanks

#19

Join Date: Dec 2008

Location: Tracy, California, USA

Posts: 3,260

Likes: 0

Received 13 Likes

on

13 Posts

There is a lot of conflicting information here. You consistently measure zero voltage at the ignition coil (0.05 volts is essentially zero). Yet you have spark enough to briefly fire the engine. You've got to have some voltage at the ignition coil if you get spark ever. The 0.03 to 0.10 voltages are the very small voltages generated as the stator charges the CDI storage capacitor through the resistance of the ignition coil primary winding. But you should see larger spikes as your meter captures the ignition event.

The trigger signal is an all or nothing event. Either the CDI gets triggered or it doesn't. So don't look at the trigger signal as a cause of "weak" spark. A trigger signal can cause intermittent hit and miss spark, but not weak spark.

Weak spark is a very subjective observation. Frustration makes it even more subjective. Cranking speed is where a CDI ignition system is at its worst. The trigger and AC ignition power voltages are directly proportional with engine speed, and cranking speed is about 2.5 times lower than idle speed. So usually with a legitimate weak spark scenario, once the quad fires while cranking, the quad speeds up a little and the voltage from the trigger and ignition power increase. This makes it more likely to fire again, and this positively regenerates. The quad starts up. But you don't see this...

Weak spark will jump a plug gap at cranking speeds, but won't jump the gap on a plug that has had the gap widened to double width.

Have the valves ever been adjusted? Hard starting when cold is a classic symptom of misadjusted valves - which is also a routine maintenance item that is supposed to be done periodically.

The trigger signal is an all or nothing event. Either the CDI gets triggered or it doesn't. So don't look at the trigger signal as a cause of "weak" spark. A trigger signal can cause intermittent hit and miss spark, but not weak spark.

Weak spark is a very subjective observation. Frustration makes it even more subjective. Cranking speed is where a CDI ignition system is at its worst. The trigger and AC ignition power voltages are directly proportional with engine speed, and cranking speed is about 2.5 times lower than idle speed. So usually with a legitimate weak spark scenario, once the quad fires while cranking, the quad speeds up a little and the voltage from the trigger and ignition power increase. This makes it more likely to fire again, and this positively regenerates. The quad starts up. But you don't see this...

Weak spark will jump a plug gap at cranking speeds, but won't jump the gap on a plug that has had the gap widened to double width.

Have the valves ever been adjusted? Hard starting when cold is a classic symptom of misadjusted valves - which is also a routine maintenance item that is supposed to be done periodically.

Okay so I removed the side cover and looked at the pick up coil in relation to the acces holes for timing, no way to measure the air gap for the pickup.

Lined up the high spot with the pick up and put cover on top alignment pin of case and could feel the gap. removed cover and loosened pickup screws and moved it in slightly. Reassembled and hooked up the LED's and still no lights while cranking. Repeated above steps two more times and now I have the LED's lighting.

Plugged the CDI back in and cranked with meter on 20 VAC scale. Meter read 0.00 with ignition on, cranking meter was reading 0.03, 0.05, 0.04, 0.03 stop cranking and meter returned to 0.00 VAC

Didn't see spark at plug.

Installed high performance CDI and checked AC voltage, meter read 0.00 ignition on, cranking it read 0.12, 0.14, 0.10 stop cranking meter returned to 0.00 VAC

Checked plug and seen what seemed like weak spark.

Installed plug and tried to start, didn't really seem to encouraging, went and bought a NGK 7HSA plug and checked spark, seemed weaker than the original that I started with.

I sprayed a little starting fluid at the air cleaner and it did fire a little but didn't stay running. Tightened all the connectors that hook up to the CDI, that didn't seem to help.

Rechecked plug for spark and don't see any, removed CDI and installed LED's and they are still lighting.

Not sure what I should try next?

All readings are same 320 ohms AC ign power pin to ground.137 ohms timing trigger to ground, 41.3 VAC ignition pin while cranking, .211VAC trigger while cranking.

Spark, air, gas, should run! To me it seems like a weak spark, could it be weak CDI or weak pick up coil

Battery is charged and starter cranks fast. Any ideas, thanks

Lined up the high spot with the pick up and put cover on top alignment pin of case and could feel the gap. removed cover and loosened pickup screws and moved it in slightly. Reassembled and hooked up the LED's and still no lights while cranking. Repeated above steps two more times and now I have the LED's lighting.

Plugged the CDI back in and cranked with meter on 20 VAC scale. Meter read 0.00 with ignition on, cranking meter was reading 0.03, 0.05, 0.04, 0.03 stop cranking and meter returned to 0.00 VAC

Didn't see spark at plug.

Installed high performance CDI and checked AC voltage, meter read 0.00 ignition on, cranking it read 0.12, 0.14, 0.10 stop cranking meter returned to 0.00 VAC

Checked plug and seen what seemed like weak spark.

Installed plug and tried to start, didn't really seem to encouraging, went and bought a NGK 7HSA plug and checked spark, seemed weaker than the original that I started with.

I sprayed a little starting fluid at the air cleaner and it did fire a little but didn't stay running. Tightened all the connectors that hook up to the CDI, that didn't seem to help.

Rechecked plug for spark and don't see any, removed CDI and installed LED's and they are still lighting.

Not sure what I should try next?

All readings are same 320 ohms AC ign power pin to ground.137 ohms timing trigger to ground, 41.3 VAC ignition pin while cranking, .211VAC trigger while cranking.

Spark, air, gas, should run! To me it seems like a weak spark, could it be weak CDI or weak pick up coil

Battery is charged and starter cranks fast. Any ideas, thanks

#20

Oops am I bad. Took another look today and found that when I removed and tightened the wire connectors I accidentlly installed the Kill wire in the coil wire slot. Explains why I lost spark.

Next I removed float bowl and found it was dry, needle was froze in to seat pulled it out and it had slight corrosion like rust on the fins of the needle. WEIRD stuff seemed like it was caused by dissimilar metals. Just my thought. Cleaned needle fins with single edge razor blade, reinstalled bowl and low and behold it fired right up!

Thanks Lynn so much for all your help.

This machine probably had three tanks of gas run through it when this all happened.

To recap my solution to this nightmare was i had good readings from generic CDI troubleshooting guide except for step b of CDI output section.

Removed kill wire from CDI connector, removed remote kill module from wiring harness.

Performed LED test of Trigger coil which it failed until I reduced air gap. Still can't figure what caused the trigger coil to stop firing the CDI.

Why would I have to decrease air gap, all screws were tight on stator including trigger coil.

Replaced original CDI which was bad with new CDI.

Confirmed there was fuel in bowl! Duh

Crank and start

Lynn many many thanks, I have one last question, the remote module when hooked up to harness prevents ATV to start. The fob flashes light when locking or unlocking as if it is working correctly.do you know if you need to perform a special procedure when reinstalling after removing?

Next I removed float bowl and found it was dry, needle was froze in to seat pulled it out and it had slight corrosion like rust on the fins of the needle. WEIRD stuff seemed like it was caused by dissimilar metals. Just my thought. Cleaned needle fins with single edge razor blade, reinstalled bowl and low and behold it fired right up!

Thanks Lynn so much for all your help.

This machine probably had three tanks of gas run through it when this all happened.

To recap my solution to this nightmare was i had good readings from generic CDI troubleshooting guide except for step b of CDI output section.

Removed kill wire from CDI connector, removed remote kill module from wiring harness.

Performed LED test of Trigger coil which it failed until I reduced air gap. Still can't figure what caused the trigger coil to stop firing the CDI.

Why would I have to decrease air gap, all screws were tight on stator including trigger coil.

Replaced original CDI which was bad with new CDI.

Confirmed there was fuel in bowl! Duh

Crank and start

Lynn many many thanks, I have one last question, the remote module when hooked up to harness prevents ATV to start. The fob flashes light when locking or unlocking as if it is working correctly.do you know if you need to perform a special procedure when reinstalling after removing?