LT230 Extended A-Arm Project

#1

Well now that I've got that fancy LT250R axle on my 230 since I bent my stock one, I kinda would like the front to match width-wise.

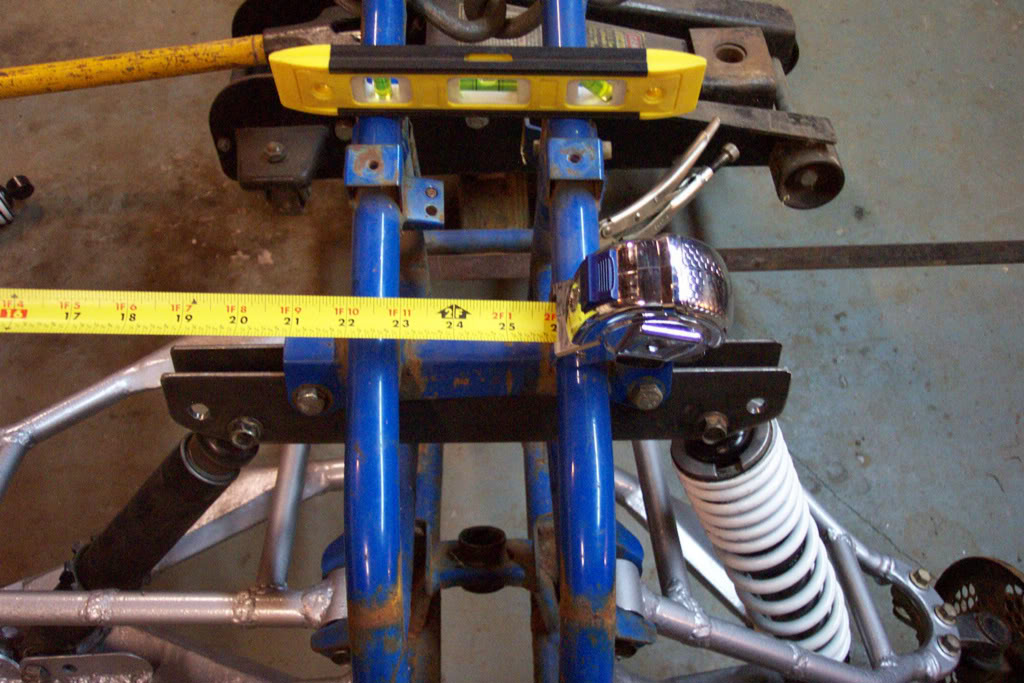

finally a reasonable width!!! yay!!!

I figure that the LT250R axle is about 3" wider than stock. In a-arm terms, that translates to 1.5" a side.

I've decided to go with the justrandy extension method, as opposed to modding 250S arms since the only ones that I could find are too pricey.

rough mock-up

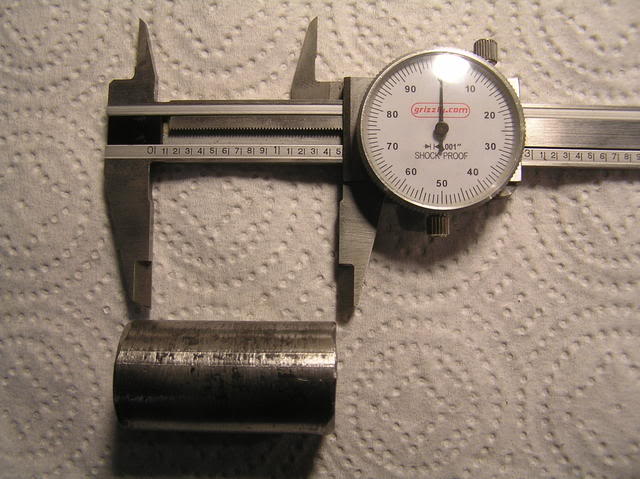

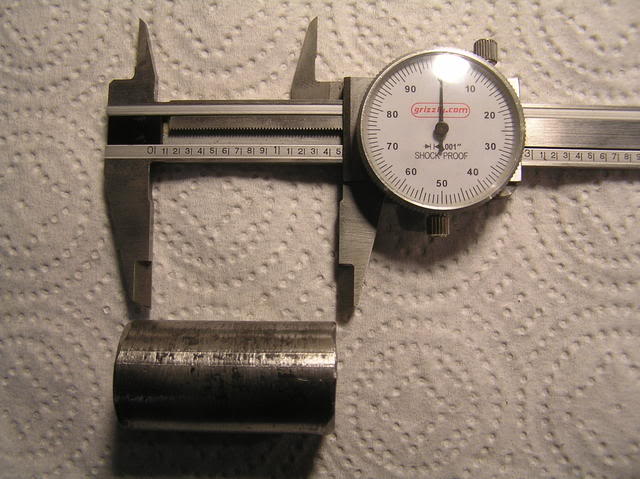

But instead of using Ford 460 wrist pins, I'm using 0.850" round mild steel tube with 0.100" wall thickness. (Pft, who am I kidding, its gas pipe from Home Cheapo!)

fancy.

not really.

I've got a spare set of lower arms and if they turn out somewhat acceptible looking, I'm going to buy some used uppers and extend them too.

So far I've cut the bearings off (theyre the fancier 87-88 style with the needle bearings instead of spherical bearings), and cut the little pipe segments.

thicker walls too.

But now I'm having some second thoughts. My original plans call for me to butt weld the tubes. I'm not so sure about that. Plus, the gas pipe is a little smaller OD than the original tube. But if I can get a meaty enough weld on there, I guess it should be ok.

eh.... idk....

But what I want to know is what shocks I can use. Obviously they are going to need to be longer. (pythagorean theorum tells me about 12.25" eye to eye for the new ones) But I want to get used ones that are nice and cheep, plus I really want a progressive rate spring.

Any opinions???

finally a reasonable width!!! yay!!!

I figure that the LT250R axle is about 3" wider than stock. In a-arm terms, that translates to 1.5" a side.

I've decided to go with the justrandy extension method, as opposed to modding 250S arms since the only ones that I could find are too pricey.

rough mock-up

But instead of using Ford 460 wrist pins, I'm using 0.850" round mild steel tube with 0.100" wall thickness. (Pft, who am I kidding, its gas pipe from Home Cheapo!)

fancy.

not really.

I've got a spare set of lower arms and if they turn out somewhat acceptible looking, I'm going to buy some used uppers and extend them too.

So far I've cut the bearings off (theyre the fancier 87-88 style with the needle bearings instead of spherical bearings), and cut the little pipe segments.

thicker walls too.

But now I'm having some second thoughts. My original plans call for me to butt weld the tubes. I'm not so sure about that. Plus, the gas pipe is a little smaller OD than the original tube. But if I can get a meaty enough weld on there, I guess it should be ok.

eh.... idk....

But what I want to know is what shocks I can use. Obviously they are going to need to be longer. (pythagorean theorum tells me about 12.25" eye to eye for the new ones) But I want to get used ones that are nice and cheep, plus I really want a progressive rate spring.

Any opinions???

#2

Good write up so far, deffinately keep documenting as you go.

I WOuld say get some late model shocks off of a Z400 or any of the 450's and make them work. They wil be ten times better than what you have and it will be hard to match an exact length and keep it reasonable in price.

Just my .02

I am trying to decide on how I want to do it myself, weather it will be the "justrandy" method, or if I want to make some late model a-arms fit with new mounting points. anyways I will start with the swing arm and watch what you do andhopefully learn as you go.

Good luck.

I WOuld say get some late model shocks off of a Z400 or any of the 450's and make them work. They wil be ten times better than what you have and it will be hard to match an exact length and keep it reasonable in price.

Just my .02

I am trying to decide on how I want to do it myself, weather it will be the "justrandy" method, or if I want to make some late model a-arms fit with new mounting points. anyways I will start with the swing arm and watch what you do andhopefully learn as you go.

Good luck.

#3

alright thanks alot man. i think im gonna go try to find some eye-to-eye lengths for z400, 400ex, and maybe even yfz450 (shortest of the 450's) shocks.

I wonder if i could make a bracket to move my upper shock mounting points up and out a little (to clear). and since the lower mounts would be out farther too, the angle should be like stock, maybe. or i could even move the lower ones out too if neccesceary. but i think that would fudge the whole leverage thingy goin on down there, and i would probably end up with a ride like a three wheeled shopping cart going down a mountain, lol. but idk.

oh and if you look into later model arms, look into the ltz250. i just looked at one close-up yesterday at my local dealer, and it looks like it may be close, idk.

I wonder if i could make a bracket to move my upper shock mounting points up and out a little (to clear). and since the lower mounts would be out farther too, the angle should be like stock, maybe. or i could even move the lower ones out too if neccesceary. but i think that would fudge the whole leverage thingy goin on down there, and i would probably end up with a ride like a three wheeled shopping cart going down a mountain, lol. but idk.

oh and if you look into later model arms, look into the ltz250. i just looked at one close-up yesterday at my local dealer, and it looks like it may be close, idk.

#4

Way to go man!!! [img]i/expressions/beer.gif[/img]

I haven't had any problems out of my butt welds, but I gussetted mine where possible. The only trouble I've had from butt welds were on the tierods when I tried to make it look nice, but when I put a lot of meat on it like you said, it holds up fine. The welds on the arms don't have so much torque stress,,,, mostly compressive and tension (unless your a-arm bearings seize up or something - which is unlikely). Since there is so little force that would bend the welds, there shouldn't be any stress fractures. Until you hit a tree anyway.... In which case you'll probably do more damage to the frame than the arms. Maybe Ugly88 can chime in with a more professional opinion.

I wouldn't worry about shock length. Just get what you want and mount them up in a trial n error method. I have several holes in the top mount and 2 or 3 on the bottom mount for moving the shock around to get just the right angle. Each shock will be different and each geometry will have to be different. Your limiting factors are the balljoints and tierods. So, you only have so much of a range of motion unless you "gullwing" the arms. In my case, the 250S shocks have 3 inches of travel (instead of 2 inches for the 230 shocks) and at a 30 dergee mouting angle, that translates to oodles of front end travel. I haven't bottomed them yet. Its possible to mount the shocks so that its geometrically impossible to ever bottom them. That's the way my rear shock is, but not the fronts.

I started out with 460 pins because that's what I had on hand. When I decided to go even wider, I ended up with the same home cheapo pipe you did. Only I bought 2 sizes... One for the bottom arms and one for the tops.

The spherical (hiem joints they're called) joints are more forgiving to welding errors. If you use those needle bearings, you'll have to have your bearings perfectly parallel with the frame. Hard to do with welding unless you have a good sturdy jig to clamp everything down.

If I could do what I want, I'd build a set of these with the hiem joints everywhere: http://www.amstarmanufacturing...ages/A-102PSP_Kit2.jpg

Those have adjustable caster and camber.

I haven't had any problems out of my butt welds, but I gussetted mine where possible. The only trouble I've had from butt welds were on the tierods when I tried to make it look nice, but when I put a lot of meat on it like you said, it holds up fine. The welds on the arms don't have so much torque stress,,,, mostly compressive and tension (unless your a-arm bearings seize up or something - which is unlikely). Since there is so little force that would bend the welds, there shouldn't be any stress fractures. Until you hit a tree anyway.... In which case you'll probably do more damage to the frame than the arms. Maybe Ugly88 can chime in with a more professional opinion.

I wouldn't worry about shock length. Just get what you want and mount them up in a trial n error method. I have several holes in the top mount and 2 or 3 on the bottom mount for moving the shock around to get just the right angle. Each shock will be different and each geometry will have to be different. Your limiting factors are the balljoints and tierods. So, you only have so much of a range of motion unless you "gullwing" the arms. In my case, the 250S shocks have 3 inches of travel (instead of 2 inches for the 230 shocks) and at a 30 dergee mouting angle, that translates to oodles of front end travel. I haven't bottomed them yet. Its possible to mount the shocks so that its geometrically impossible to ever bottom them. That's the way my rear shock is, but not the fronts.

I started out with 460 pins because that's what I had on hand. When I decided to go even wider, I ended up with the same home cheapo pipe you did. Only I bought 2 sizes... One for the bottom arms and one for the tops.

The spherical (hiem joints they're called) joints are more forgiving to welding errors. If you use those needle bearings, you'll have to have your bearings perfectly parallel with the frame. Hard to do with welding unless you have a good sturdy jig to clamp everything down.

If I could do what I want, I'd build a set of these with the hiem joints everywhere: http://www.amstarmanufacturing...ages/A-102PSP_Kit2.jpg

Those have adjustable caster and camber.

#6

You should not have a problem with the butt welds. I woul dtake some of that home cheapo pipe stock, and practice a few welds, it will let you get your heat and wire speed settings perfect for full penetration, and practice keeping the bead going around the arc of the pipe. Full penetration is where the weld gets ultimate strength. Bevel the ends of the pipe where they meet to help obtain a good bead and weld.

#7

oh man, i dont even know where to begin!!!

i guess i should start by thanking you, since you just gave me a whole bunch of new ideas!

first off, since it looks like im getting myself into quite a big project, i might as well tack on a little more width while im at it to make things more rewarding in the end hahaha (and for the rear i'll get some spacers i guess)

im thinking an extra 2.5" per side, as opposed to my intial plans for +1.5"

however, i still have a stock swingarm, and i remember you saying something along the lines of "four wheeled vehicles that are wider than they are long don't like to go straight". do you think this will be a problem for me?

if i need to, i guess ill tack on an extra 2", but i really dont want to take my bike out of commission too long, so i guess i would go for another used swinger.

oh and another thing, you've raised a point that i cant believe i overlooked. heims!!! i think what im going to do is discard the oem bearings entireley, and weld a big 'ol nut onto one end of my extension tube. then weld the other end onto the remainder of the arm as planned, and toss a couple heims (mcmaster-carr p/n: 59935K83) in the ends with some thin jam nuts and be on my way! that would be super-forgiving as far as mild misalignment goes, and they'd be fully adjustable by a good inch or so, be easy to replace, and look SO FANCY!!!

and your gussests are BEASTLY!!! i'm definatley doing something similar. what did you use? 1/8" plate and boxed everything in?

lastly, how much did you actually end up adding width-wise? looks like ALOT. and does the front end sit really high now? also, how does the oem spring rate on those (appears to be 250s?) shocks work out?

oh man im gettin excited about this whole project hahaha!

and once again, THANKS ALOT MAN

i guess i should start by thanking you, since you just gave me a whole bunch of new ideas!

first off, since it looks like im getting myself into quite a big project, i might as well tack on a little more width while im at it to make things more rewarding in the end hahaha (and for the rear i'll get some spacers i guess)

im thinking an extra 2.5" per side, as opposed to my intial plans for +1.5"

however, i still have a stock swingarm, and i remember you saying something along the lines of "four wheeled vehicles that are wider than they are long don't like to go straight". do you think this will be a problem for me?

if i need to, i guess ill tack on an extra 2", but i really dont want to take my bike out of commission too long, so i guess i would go for another used swinger.

oh and another thing, you've raised a point that i cant believe i overlooked. heims!!! i think what im going to do is discard the oem bearings entireley, and weld a big 'ol nut onto one end of my extension tube. then weld the other end onto the remainder of the arm as planned, and toss a couple heims (mcmaster-carr p/n: 59935K83) in the ends with some thin jam nuts and be on my way! that would be super-forgiving as far as mild misalignment goes, and they'd be fully adjustable by a good inch or so, be easy to replace, and look SO FANCY!!!

and your gussests are BEASTLY!!! i'm definatley doing something similar. what did you use? 1/8" plate and boxed everything in?

lastly, how much did you actually end up adding width-wise? looks like ALOT. and does the front end sit really high now? also, how does the oem spring rate on those (appears to be 250s?) shocks work out?

oh man im gettin excited about this whole project hahaha!

and once again, THANKS ALOT MAN

Trending Topics

#8

oh wow, i took so long typing my last reply ugly88 snuck that last one in without me noticing hahaha.

but to avoid confusion, my last giant reply was to justrandy. this is to ugly88:

yeah that's exactly what i was thinking. i've got plenty of it anyways (they make u buy the whole 8 or 10 foot section lol).

but to avoid confusion, my last giant reply was to justrandy. this is to ugly88:

yeah that's exactly what i was thinking. i've got plenty of it anyways (they make u buy the whole 8 or 10 foot section lol).

#9

#10

<div class="FTQUOTE"><begin quote>Originally posted by: lt230sman

oh man, i dont even know where to begin!!!

i guess i should start by thanking you, since you just gave me a whole bunch of new ideas!</end quote></div>

No problem! [img]i/expressions/beer.gif[/img] I think we'll all benefit by sharing ideas. I'm sure you'll take it farther than I did. And the next guy will improve it even more and so on.

<div class="FTQUOTE"><begin quote>first off, since it looks like im getting myself into quite a big project, i might as well tack on a little more width while im at it to make things more rewarding in the end hahaha (and for the rear i'll get some spacers i guess)</end quote></div>

The 460 pins I used were 3.25 inches. I think that put me in the 46-47 inch range measured from the very extents of the tires. But I also had flipped rims at the time. So, later on I added the tube you're using to the 460 pins and put stock rims back on. Its about 48 inches on the nose now. (more if I squish the front all the way down - might be 49 then). I'm pretty sure I added 5 inches to each arm (3.25 + 1.75). That might be a little much for tight trail riding, but no issues other than that. I'm not sure what I would do if I had it to do again, but I certainly wouldn't go less than +4 on each arm. +5 is the most because I want it to fit in the back of my Ranger truck bed.

One good thing about being so wide is the mud totally misses me by being thrown so far over to the side. So long as I keep the wheels straight that is. [img]i/expressions/face-icon-small-happy.gif[/img]

<div class="FTQUOTE"><begin quote>however, i still have a stock swingarm, and i remember you saying something along the lines of "four wheeled vehicles that are wider than they are long don't like to go straight". do you think this will be a problem for me?</end quote></div>

Mine was wide before it was long, so I'm not sure how much of a big deal it is. But if a quad was something like 10ft wide and 2 ft long and the right front wheel hits a bump, that would throw you off to the right since 10ft of leverage can easily overpower 2ft. But if the quad was 2 ft wide and 10ft long and you hit the same bump, the 2 ft of leverage wouldn't affect the straight line tracking because you have 10ft of "rudder" behind you that simply wouldn't budge. If you look at the spec for all the race quads, they're all a couple inches longer than they are wide.

<div class="FTQUOTE"><begin quote>oh and another thing, you've raised a point that i cant believe i overlooked. heims!!! i think what im going to do is discard the oem bearings entireley, and weld a big 'ol nut onto one end of my extension tube. then weld the other end onto the remainder of the arm as planned, and toss a couple heims (mcmaster-carr p/n: 59935K83) in the ends with some thin jam nuts and be on my way! that would be super-forgiving as far as mild misalignment goes, and they'd be fully adjustable by a good inch or so, be easy to replace, and look SO FANCY!!!</end quote></div>

That's the way to go I think. Then you have the adjustable caster and camber. Comes in handy when you don't know exactly how its going to steer when its all done. My steering was super hard and I ended up having to hack off the upper balljoint mount and reweld it a good inch forward. I'd like the capability to dial it in perfectly without having to cut n weld 20-30 times.

<div class="FTQUOTE"><begin quote>and your gussests are BEASTLY!!! i'm definatley doing something similar. what did you use? 1/8" plate and boxed everything in?</end quote></div>

I didn't know how much I needed and wanted to err on the side of safety. I can't imagine the force it would take to bend the bottom arm. I probably went overboard on it, but I was also going for a decent appearance.

Its just some thin angle I had laying around and a piece of flat steel over it. The bottom doesn't look as nice as the top since I didn't cap off the angle with the flat. But who sees the bottom? I have some pics somewhere....

<div class="FTQUOTE"><begin quote>lastly, how much did you actually end up adding width-wise? looks like ALOT. and does the front end sit really high now? also, how does the oem spring rate on those (appears to be 250s?) shocks work out?</end quote></div>

The springs are dual rate. Probably the best 250 class stock springs you can find. They have 6 soft coils and 6 hard ones. It would be nice to have some adjustability to the shock, but, lots of things would be nice. [img]i/expressions/face-icon-small-happy.gif[/img] These only cost 40 bucks. [img]i/expressions/face-icon-small-wink.gif[/img]

I made the front as tall as I can get it on purpose. When I first got the quad I went to the mountain trails and was white-knuckling it anytime I had to go downhill. Now I can blast downhill with confidence.... And I don't lose any hill climbing ability.

I also lowered the back and ended up with a 29-30 inch seat height. I feel very safe and confident riding anywhere except in really tight trails. Its wide, long, tall enough to clear rocks yet low center of gravity. That's what I set out to do.

See if I can find some pics now.....

oh man, i dont even know where to begin!!!

i guess i should start by thanking you, since you just gave me a whole bunch of new ideas!</end quote></div>

No problem! [img]i/expressions/beer.gif[/img] I think we'll all benefit by sharing ideas. I'm sure you'll take it farther than I did. And the next guy will improve it even more and so on.

<div class="FTQUOTE"><begin quote>first off, since it looks like im getting myself into quite a big project, i might as well tack on a little more width while im at it to make things more rewarding in the end hahaha (and for the rear i'll get some spacers i guess)</end quote></div>

The 460 pins I used were 3.25 inches. I think that put me in the 46-47 inch range measured from the very extents of the tires. But I also had flipped rims at the time. So, later on I added the tube you're using to the 460 pins and put stock rims back on. Its about 48 inches on the nose now. (more if I squish the front all the way down - might be 49 then). I'm pretty sure I added 5 inches to each arm (3.25 + 1.75). That might be a little much for tight trail riding, but no issues other than that. I'm not sure what I would do if I had it to do again, but I certainly wouldn't go less than +4 on each arm. +5 is the most because I want it to fit in the back of my Ranger truck bed.

One good thing about being so wide is the mud totally misses me by being thrown so far over to the side. So long as I keep the wheels straight that is. [img]i/expressions/face-icon-small-happy.gif[/img]

<div class="FTQUOTE"><begin quote>however, i still have a stock swingarm, and i remember you saying something along the lines of "four wheeled vehicles that are wider than they are long don't like to go straight". do you think this will be a problem for me?</end quote></div>

Mine was wide before it was long, so I'm not sure how much of a big deal it is. But if a quad was something like 10ft wide and 2 ft long and the right front wheel hits a bump, that would throw you off to the right since 10ft of leverage can easily overpower 2ft. But if the quad was 2 ft wide and 10ft long and you hit the same bump, the 2 ft of leverage wouldn't affect the straight line tracking because you have 10ft of "rudder" behind you that simply wouldn't budge. If you look at the spec for all the race quads, they're all a couple inches longer than they are wide.

<div class="FTQUOTE"><begin quote>oh and another thing, you've raised a point that i cant believe i overlooked. heims!!! i think what im going to do is discard the oem bearings entireley, and weld a big 'ol nut onto one end of my extension tube. then weld the other end onto the remainder of the arm as planned, and toss a couple heims (mcmaster-carr p/n: 59935K83) in the ends with some thin jam nuts and be on my way! that would be super-forgiving as far as mild misalignment goes, and they'd be fully adjustable by a good inch or so, be easy to replace, and look SO FANCY!!!</end quote></div>

That's the way to go I think. Then you have the adjustable caster and camber. Comes in handy when you don't know exactly how its going to steer when its all done. My steering was super hard and I ended up having to hack off the upper balljoint mount and reweld it a good inch forward. I'd like the capability to dial it in perfectly without having to cut n weld 20-30 times.

<div class="FTQUOTE"><begin quote>and your gussests are BEASTLY!!! i'm definatley doing something similar. what did you use? 1/8" plate and boxed everything in?</end quote></div>

I didn't know how much I needed and wanted to err on the side of safety. I can't imagine the force it would take to bend the bottom arm. I probably went overboard on it, but I was also going for a decent appearance.

Its just some thin angle I had laying around and a piece of flat steel over it. The bottom doesn't look as nice as the top since I didn't cap off the angle with the flat. But who sees the bottom? I have some pics somewhere....

<div class="FTQUOTE"><begin quote>lastly, how much did you actually end up adding width-wise? looks like ALOT. and does the front end sit really high now? also, how does the oem spring rate on those (appears to be 250s?) shocks work out?</end quote></div>

The springs are dual rate. Probably the best 250 class stock springs you can find. They have 6 soft coils and 6 hard ones. It would be nice to have some adjustability to the shock, but, lots of things would be nice. [img]i/expressions/face-icon-small-happy.gif[/img] These only cost 40 bucks. [img]i/expressions/face-icon-small-wink.gif[/img]

I made the front as tall as I can get it on purpose. When I first got the quad I went to the mountain trails and was white-knuckling it anytime I had to go downhill. Now I can blast downhill with confidence.... And I don't lose any hill climbing ability.

I also lowered the back and ended up with a 29-30 inch seat height. I feel very safe and confident riding anywhere except in really tight trails. Its wide, long, tall enough to clear rocks yet low center of gravity. That's what I set out to do.

See if I can find some pics now.....