SunL 90 lost its spark

#1

My sonís SunL 90 was not idling (hasnít since summer). I performed the clip ring movement to richen up for the cold weather and adjusted the idle screw about a half turn. Got the machine to idle but was having a real tough time getting it to start. I had to use a portable jumper box do to the small battery giving up. She would only start with the help of "Starter Fluid" spray. Once running and warm, it would dye out when re-installing the freshly cleaned and oiled air filter.

After a while of messing around with the carborator, she decided not to start at all. Found out I lost the spark. I tried 3 other plugs with no luck. Any ideas would be greatly appreciated. If I can get the spark back, I think I can finish with the carb adjustments.

Thanks in advance.

After a while of messing around with the carborator, she decided not to start at all. Found out I lost the spark. I tried 3 other plugs with no luck. Any ideas would be greatly appreciated. If I can get the spark back, I think I can finish with the carb adjustments.

Thanks in advance.

#2

#4

#6

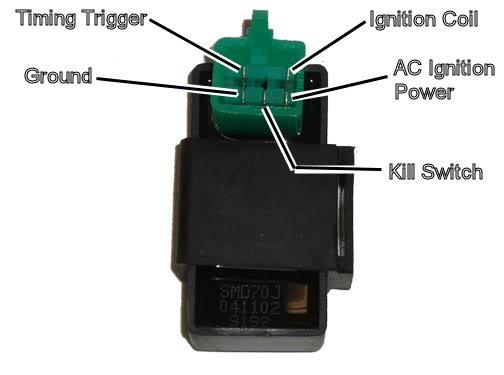

The first thing to check is whether the kill switch circuitry is keeping you from getting spark. The kill switch(es) work by shorting the "Kill switch" connection of the CDI to ground, which shorts out an internal high voltage (but low current) supply, thus preventing spark. There are 4 common kill switches on chinese quads, any one of which can be shorted and prevent spark. They are listed below (not all quads have all of these installed):

1) One half of the two section ignition switch: When you turn the ignition switch off this switch section shorts the kill switch wire to ground and shuts down the engine.

2) The left handlebar kill switch: This switch allows you to kill the engine without letting go of the handlebars. It is usually center off, with left or right movement killing the engine. On some of these switches the kill switch latches on, and can only be reset by moving the switch to the center position and pushing in until it goes "click". Most people who have this style handlebar kill switch has been 'got' by the the latching feature more than once.

3) Tether cord pull switch: This switch allows for a cord to be tied to a rope contolled by parents, or even tied to the riders wrist. When the tether cord is pulled, a plug comes out of a switch. The switch contacts snap closed - killing the engine.

4) Radio link remote control module. This module (if installed) also has the ability to kill the engine by remote radio link by shorting the kill line to ground.

To test the kill switch circuitry, unplug the CDI and measure the resistance (in ohms) of the kill switch wire in the wiring harness connector to ground. When doing this test have everything set to the "run" mode - Ignition switch on, handlebar kill switch off, tether switch plug cord installed, etc. It should read open circuit (infinite ohms). If it reads shorted or low resistance then you have a problem in the kill switch circuitry. Start unplugging each switch until the short goes away. Then you know which switch is defective.

If you find you don't have kill switch issues then the next step will be to measure the stator output voltages (power and trigger). Most no spark issues have to do with kill switches so let's start there.

Note: Whenever the quad engine is turning (cranking or running) there is high voltage (80-300 volts peak) on the kill switch wires. Watch your fingers when working on this wiring.

1) One half of the two section ignition switch: When you turn the ignition switch off this switch section shorts the kill switch wire to ground and shuts down the engine.

2) The left handlebar kill switch: This switch allows you to kill the engine without letting go of the handlebars. It is usually center off, with left or right movement killing the engine. On some of these switches the kill switch latches on, and can only be reset by moving the switch to the center position and pushing in until it goes "click". Most people who have this style handlebar kill switch has been 'got' by the the latching feature more than once.

3) Tether cord pull switch: This switch allows for a cord to be tied to a rope contolled by parents, or even tied to the riders wrist. When the tether cord is pulled, a plug comes out of a switch. The switch contacts snap closed - killing the engine.

4) Radio link remote control module. This module (if installed) also has the ability to kill the engine by remote radio link by shorting the kill line to ground.

To test the kill switch circuitry, unplug the CDI and measure the resistance (in ohms) of the kill switch wire in the wiring harness connector to ground. When doing this test have everything set to the "run" mode - Ignition switch on, handlebar kill switch off, tether switch plug cord installed, etc. It should read open circuit (infinite ohms). If it reads shorted or low resistance then you have a problem in the kill switch circuitry. Start unplugging each switch until the short goes away. Then you know which switch is defective.

If you find you don't have kill switch issues then the next step will be to measure the stator output voltages (power and trigger). Most no spark issues have to do with kill switches so let's start there.

Note: Whenever the quad engine is turning (cranking or running) there is high voltage (80-300 volts peak) on the kill switch wires. Watch your fingers when working on this wiring.

#7

Trending Topics

#8

#9

With the CDI disconnected (this is important):

Stator Tests:

Measure the AC Ignition power pin voltage in the wiring harness (at the CDI connector) to ground while cranking. It should measure 80 volts AC or so. Note this is AC voltage (not DC) so set your meter accordingly.

Measure the Timing Trigger pin voltage in the wiring harness to ground while cranking. This should measure 0.2 to 0.5 volts AC. Note that this is a low voltage and you will have to set your scale way down to the lowest AC voltage setting.

With the engine stopped measure the AC Ignition Power pin resistance (in ohms) to ground. Ignition switch and/or kill switch settings don't matter for this test. It should read 450 ohms or so.

With the engine stopped measure the Timing Trigger pin resistance to ground. Once again the ignition/kill switch settings don't matter for this test. It should measure 150 ohms or so.

What these tests are doing: The CDI is powered off a moderately high voltage AC supply running from 80 to several hundred volts. This power supply comes off the stator. When you measure the AC ignition power pin you are measuring this supply's AC voltage output while cranking the engine, and measuring for the continuity of the AC power winding in the stator while the engine is stopped.

The Trigger pin is a signal that comes off a winding in the stator mounted outside the flywheel that tells the CDI when to fire the spark plug, It is a very narrow plus and minus pulse pair that is about +/- 5 volts high at trigger time (at cranking speeds), but mostly sits at zero volts between triggers. Voltmeters aren't very good at measuring these kind of narrow pulse waveforms so the actual AC reading you get is much, much lower than the 5 volts. But you should measure something here (not zero volts AC) while cranking. The trigger pin resistance measurements is measuring continuity of the trigger puckup coil.

CDI and Ignition Coil Continuity Tests:

Measure the resistance of the ground pin in the wiring harness at the CDI connector to ground. It should read zero ohms.

Measure the resistance of the Ignition Coil pin in the wiring harness at the CDI connector to ground. It should read a very low resistance (like 0.5 to 2 ohms), but it should not read zero ohms.

Pull off the spark plug wire and measure the resistance of the spark plug wire to ground. This reading varies a lot from quad to quad. It should read more than 100 ohms, but may read as high as 10,000 ohms. It should not be shorted, nor should it be open. The difference is whether radio frequency interference suppression resistor is in the output lead.

What these test are doing:

The CDI needs a ground to work. The first test verifies that.

The output of the CDI to the ignition coil is a very narrow high voltage (several hundred volts) and high frequency (30 kilohertz) pulse waveform. This is really hard to measure with a voltmeter. But you can measure the resistance of the coil primary through the wiring harness to ground just to make sure it is hooked up. That's what the Ignition Coil pin test above does.

The ignition coil secondary should not be shorted or open. You can verify this with a meter. This is a far cry from measuring the breakdown voltage of the ignition coil insulation, or whether ther are shorted turns in the secondary, etc. If all you have is a voltmeter you do the best you can.

I'll follow up tomorrow morning with a couple more tests and a summary.

Stator Tests:

Measure the AC Ignition power pin voltage in the wiring harness (at the CDI connector) to ground while cranking. It should measure 80 volts AC or so. Note this is AC voltage (not DC) so set your meter accordingly.

Measure the Timing Trigger pin voltage in the wiring harness to ground while cranking. This should measure 0.2 to 0.5 volts AC. Note that this is a low voltage and you will have to set your scale way down to the lowest AC voltage setting.

With the engine stopped measure the AC Ignition Power pin resistance (in ohms) to ground. Ignition switch and/or kill switch settings don't matter for this test. It should read 450 ohms or so.

With the engine stopped measure the Timing Trigger pin resistance to ground. Once again the ignition/kill switch settings don't matter for this test. It should measure 150 ohms or so.

What these tests are doing: The CDI is powered off a moderately high voltage AC supply running from 80 to several hundred volts. This power supply comes off the stator. When you measure the AC ignition power pin you are measuring this supply's AC voltage output while cranking the engine, and measuring for the continuity of the AC power winding in the stator while the engine is stopped.

The Trigger pin is a signal that comes off a winding in the stator mounted outside the flywheel that tells the CDI when to fire the spark plug, It is a very narrow plus and minus pulse pair that is about +/- 5 volts high at trigger time (at cranking speeds), but mostly sits at zero volts between triggers. Voltmeters aren't very good at measuring these kind of narrow pulse waveforms so the actual AC reading you get is much, much lower than the 5 volts. But you should measure something here (not zero volts AC) while cranking. The trigger pin resistance measurements is measuring continuity of the trigger puckup coil.

CDI and Ignition Coil Continuity Tests:

Measure the resistance of the ground pin in the wiring harness at the CDI connector to ground. It should read zero ohms.

Measure the resistance of the Ignition Coil pin in the wiring harness at the CDI connector to ground. It should read a very low resistance (like 0.5 to 2 ohms), but it should not read zero ohms.

Pull off the spark plug wire and measure the resistance of the spark plug wire to ground. This reading varies a lot from quad to quad. It should read more than 100 ohms, but may read as high as 10,000 ohms. It should not be shorted, nor should it be open. The difference is whether radio frequency interference suppression resistor is in the output lead.

What these test are doing:

The CDI needs a ground to work. The first test verifies that.

The output of the CDI to the ignition coil is a very narrow high voltage (several hundred volts) and high frequency (30 kilohertz) pulse waveform. This is really hard to measure with a voltmeter. But you can measure the resistance of the coil primary through the wiring harness to ground just to make sure it is hooked up. That's what the Ignition Coil pin test above does.

The ignition coil secondary should not be shorted or open. You can verify this with a meter. This is a far cry from measuring the breakdown voltage of the ignition coil insulation, or whether ther are shorted turns in the secondary, etc. If all you have is a voltmeter you do the best you can.

I'll follow up tomorrow morning with a couple more tests and a summary.

#10

Test results blow in red bold (I'm not yelling ):

):

Measure the AC Ignition power pin voltage in the wiring harness (at the CDI connector) to ground while cranking. It should measure 80 volts AC or so: 36 volts

Measure the Timing Trigger pin voltage in the wiring harness to ground while cranking. This should measure 0.2 to 0.5 volts AC.: 0 volts

With the engine stopped measure the AC Ignition Power pin resistance (in ohms) to ground. Ignition switch and/or kill switch settings don't matter for this test. It should read 450 ohms or so. 0 with switch on and off

With the engine stopped measure the Timing Trigger pin resistance to ground. Once again the ignition/kill switch settings don't matter for this test. It should measure 150 ohms or so. 0 with switch on and off

*_CDI and Ignition Coil Continuity Tests:_*

Measure the resistance of the ground pin in the wiring harness at the CDI connector to ground. It should read zero ohms. 4.2 ohms

Measure the resistance of the Ignition Coil pin in the wiring harness at the CDI connector to ground. 3.3 ohms

Pull off the spark plug wire and measure the resistance of the spark plug wire to ground: Open curcuit

What the heck

):

):Measure the AC Ignition power pin voltage in the wiring harness (at the CDI connector) to ground while cranking. It should measure 80 volts AC or so: 36 volts

Measure the Timing Trigger pin voltage in the wiring harness to ground while cranking. This should measure 0.2 to 0.5 volts AC.: 0 volts

With the engine stopped measure the AC Ignition Power pin resistance (in ohms) to ground. Ignition switch and/or kill switch settings don't matter for this test. It should read 450 ohms or so. 0 with switch on and off

With the engine stopped measure the Timing Trigger pin resistance to ground. Once again the ignition/kill switch settings don't matter for this test. It should measure 150 ohms or so. 0 with switch on and off

*_CDI and Ignition Coil Continuity Tests:_*

Measure the resistance of the ground pin in the wiring harness at the CDI connector to ground. It should read zero ohms. 4.2 ohms

Measure the resistance of the Ignition Coil pin in the wiring harness at the CDI connector to ground. 3.3 ohms

Pull off the spark plug wire and measure the resistance of the spark plug wire to ground: Open curcuit

What the heck